Page 282 - Compression Machinery for Oil and Gas

P. 282

Screw Compressors Chapter 6 267

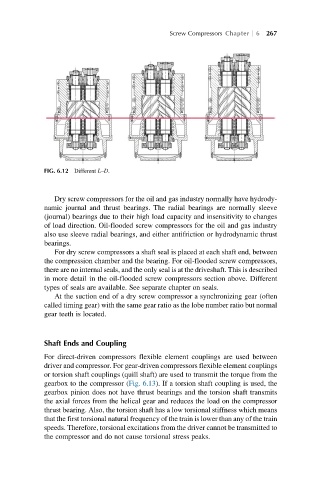

FIG. 6.12 Different L–D.

Dry screw compressors for the oil and gas industry normally have hydrody-

namic journal and thrust bearings. The radial bearings are normally sleeve

(journal) bearings due to their high load capacity and insensitivity to changes

of load direction. Oil-flooded screw compressors for the oil and gas industry

also use sleeve radial bearings, and either antifriction or hydrodynamic thrust

bearings.

For dry screw compressors a shaft seal is placed at each shaft end, between

the compression chamber and the bearing. For oil-flooded screw compressors,

there are no internal seals, and the only seal is at the driveshaft. This is described

in more detail in the oil-flooded screw compressors section above. Different

types of seals are available. See separate chapter on seals.

At the suction end of a dry screw compressor a synchronizing gear (often

called timing gear) with the same gear ratio as the lobe number ratio but normal

gear teeth is located.

Shaft Ends and Coupling

For direct-driven compressors flexible element couplings are used between

driver and compressor. For gear-driven compressors flexible element couplings

or torsion shaft couplings (quill shaft) are used to transmit the torque from the

gearbox to the compressor (Fig. 6.13). If a torsion shaft coupling is used, the

gearbox pinion does not have thrust bearings and the torsion shaft transmits

the axial forces from the helical gear and reduces the load on the compressor

thrust bearing. Also, the torsion shaft has a low torsional stiffness which means

that the first torsional natural frequency of the train is lower than any of the train

speeds. Therefore, torsional excitations from the driver cannot be transmitted to

the compressor and do not cause torsional stress peaks.