Page 280 - Compression Machinery for Oil and Gas

P. 280

Screw Compressors Chapter 6 265

Design Features

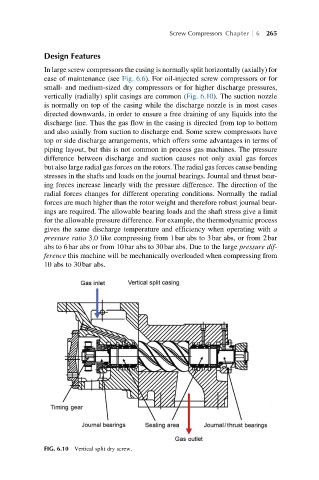

In large screw compressors the casing is normally split horizontally (axially) for

ease of maintenance (see Fig. 6.6). For oil-injected screw compressors or for

small- and medium-sized dry compressors or for higher discharge pressures,

vertically (radially) split casings are common (Fig. 6.10). The suction nozzle

is normally on top of the casing while the discharge nozzle is in most cases

directed downwards, in order to ensure a free draining of any liquids into the

discharge line. Thus the gas flow in the casing is directed from top to bottom

and also axially from suction to discharge end. Some screw compressors have

top or side discharge arrangements, which offers some advantages in terms of

piping layout, but this is not common in process gas machines. The pressure

difference between discharge and suction causes not only axial gas forces

but also large radial gas forces on the rotors. The radial gas forces cause bending

stresses in the shafts and loads on the journal bearings. Journal and thrust bear-

ing forces increase linearly with the pressure difference. The direction of the

radial forces changes for different operating conditions. Normally the radial

forces are much higher than the rotor weight and therefore robust journal bear-

ings are required. The allowable bearing loads and the shaft stress give a limit

for the allowable pressure difference. For example, the thermodynamic process

gives the same discharge temperature and efficiency when operating with a

pressure ratio 3.0 like compressing from 1bar abs to 3bar abs, or from 2bar

abs to 6bar abs or from 10bar abs to 30bar abs. Due to the large pressure dif-

ference this machine will be mechanically overloaded when compressing from

10 abs to 30bar abs.

FIG. 6.10 Vertical split dry screw.