Page 255 - Corrosion Engineering Principles and Practice

P. 255

228 C h a p t e r 7 C o r r o s i o n F a i l u r e s , F a c t o r s , a n d C e l l s 229

Graphite

Platinum

Ni-Cr-Mo-Cu-Si alloy G

Ni-Cr-Mo alloy C

Titanium

Alloy 825

Alloy 20

316, 317 SS (passive)

Monel 400, K-500

Silver

302, 304, 321, 347 SS (passive)

Nickel 200

Silver bronze alloys

Alloy 600 (Passive)

Nickel-aluminium bronze

70–30 copper-nickel

Lead

430 SS (Passive)

80–20 copper-nickel

90–10 copper-nickel

Nickel silver

410, 416 SS (Passive)

Tin bronzes (G&M)

Silicon bronze

Manganese bronze

Admiralty, aluminium brasses

Pb-Sn Solder (50/50)

Copper

Tin

Naval, yellow, red brasses

Aluminium bronze

316, 317 SS (Active)

Alloy 600 (Active)

Austenitic nickel cast iron

302, 304, 321, 347 SS (Active)

410, 416, 430 SS (Active)

Low alloy steel

Mild steel, cast iron

Cadmium

Aluminium alloys

Zinc

Magnesium

–2 –1.5 –1 –0.5 0 0.5

Potential (V vs. SCE)

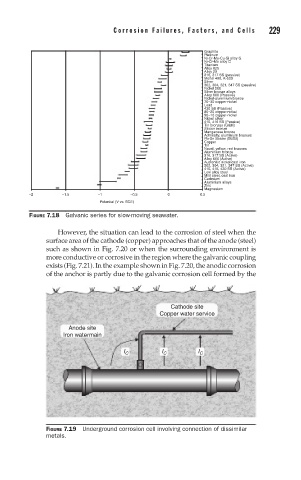

FIGURE 7.18 Galvanic series for slow-moving seawater.

However, the situation can lead to the corrosion of steel when the

surface area of the cathode (copper) approaches that of the anode (steel)

such as shown in Fig. 7.20 or when the surrounding environment is

more conductive or corrosive in the region where the galvanic coupling

exists (Fig. 7.21). In the example shown in Fig. 7.20, the anodic corrosion

of the anchor is partly due to the galvanic corrosion cell formed by the

Cathode site

Copper water service

Anode site

Iron watermain

I C I C I C

FIGURE 7.19 Underground corrosion cell involving connection of dissimilar

metals.