Page 308 - Corrosion Engineering Principles and Practice

P. 308

278 C h a p t e r 8 C o r r o s i o n b y W a t e r 279

2

1.6

Corrosion rate (mm/y) 1.2

0.8

0.4

0

0 5 10 15 20 25 30 35

Sodium chloride (%)

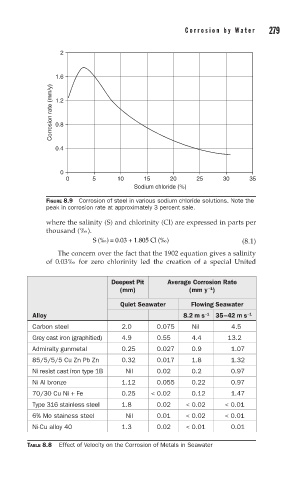

FIGURE 8.9 Corrosion of steel in various sodium chloride solutions. Note the

peak in corrosion rate at approximately 3 percent sale.

where the salinity (S) and chlorinity (Cl) are expressed in parts per

thousand (‰).

S (‰) = 0.03 + 1.805 Cl (‰) (8.1)

The concern over the fact that the 1902 equation gives a salinity

of 0.03‰ for zero chlorinity led the creation of a special United

Deepest Pit Average Corrosion Rate

(mm) (mm y )

-1

Quiet Seawater Flowing Seawater

Alloy 8.2 m s -1 35 – 42 m s -1

Carbon steel 2.0 0.075 Nil 4.5

Grey cast iron (graphitied) 4.9 0.55 4.4 13.2

Admiralty gunmetal 0.25 0.027 0.9 1.07

85/5/5/5 Cu Zn Pb Zn 0.32 0.017 1.8 1.32

Ni resist cast iron type 1B Nil 0.02 0.2 0.97

Ni Al bronze 1.12 0.055 0.22 0.97

70/30 Cu Ni + Fe 0.25 < 0.02 0.12 1.47

Type 316 stainless steel 1.8 0.02 < 0.02 < 0.01

6% Mo stainess steel Nil 0.01 < 0.02 < 0.01

Ni-Cu alloy 40 1.3 0.02 < 0.01 0.01

TABLE 8.8 Effect of Velocity on the Corrosion of Metals in Seawater