Page 738 - Corrosion Engineering Principles and Practice

P. 738

C h a p t e r 1 5

690

0.42

> 0.40

> 0.73

0.32

0.45

> 0.9

> 1.2

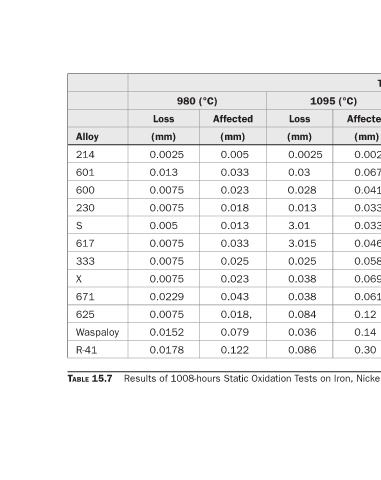

Results of 1008-hours Static Oxidation Tests on Iron, Nickel, and Cobalt Alloys in Flowing Air at Different Temperatures

0.086

> 0.73

0.18

> 0.40

0.27

> 0.9

> 1.2

0.099

0.147

0.086

0.46

0.44

0.33

0.1

0.066

0.028

0.079

0.41

0.05

0.21

0.11

Temperature

0.058

0.069

0.061

0.046

0.30

0.14

0.12

1095 (°C) 1250 (°C) 1150 (°C) Affected Loss Affected Loss Affected (mm) (mm) (mm) (mm) (mm) 0.018 0.005 0.0075 0.005 0.0025 0.19 0.11 0.135 0.061 0.067 0.21 0.13 0.074 0.043 0.041 0.20 0.11 0.086 0.058 0.033 > 0.81 > 0.81 0.043 0.025 0.033 H i g h - Te m p e r a t u r e

Loss (mm) 0.0025 0.03 O.028 0.013 3.01 3.015 0.025 0.038 0.038 0.084 0.036 0.086

Affected (mm) 0.005 0.033 0.023 0.018 0.013 0.033 0.025 0.023 0.043 0.018, 0.079 0.122

980 (°C)

Loss (mm) 0.0025 0.013 0.0075 0.0075 0.005 0.0075 0.0075 0.0075 0.0229 0.0075 0.0152 0.0178

Alloy 214 601 600 230 S 617 333 X 671 625 Waspaloy R-41 TABLE 15.7