Page 739 - Corrosion Engineering Principles and Practice

P. 739

690 C h a p t e r 1 5 H i g h - Te m p e r a t u r e C o r r o s i o n 691

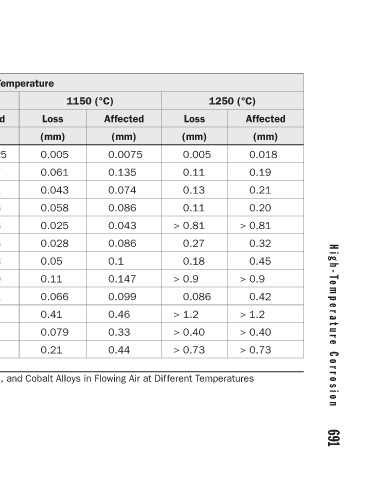

Affected (mm) 0.018 0.19 0.21 0.20 > 0.81 0.32 0.45 > 0.9 0.42 > 1.2 > 0.40 > 0.73

1250 (°C)

Loss (mm) 0.005 0.11 0.13 0.11 > 0.81 0.27 0.18 > 0.9 0.086 > 1.2 > 0.40 > 0.73

Affected (mm) 0.0075 0.135 0.074 0.086 0.043 0.086 0.1 0.147 0.099 0.46 0.33 0.44

1150 (°C)

Temperature Loss (mm) 0.005 0.0025 0.061 0.043 0.058 0.025 0.028 0.05 0.11 0.066 0.41 0.079 0.21 Results of 1008-hours Static Oxidation Tests on Iron, Nickel, and Cobalt Alloys in Flowing Air at Different Temperatures

1095 (°C) Affected (mm) 0.067 0.041 0.033 0.033 0.046 0.058 0.069 0.061 0.12 0.14 0.30

Loss (mm) 0.0025 0.03 O.028 0.013 3.01 3.015 0.025 0.038 0.038 0.084 0.036 0.086

Affected (mm) 0.005 0.033 0.023 0.018 0.013 0.033 0.025 0.023 0.043 0.018, 0.079 0.122

980 (°C)

Loss (mm) 0.0025 0.013 0.0075 0.0075 0.005 0.0075 0.0075 0.0075 0.0229 0.0075 0.0152 0.0178

Alloy 214 601 600 230 S 617 333 X 671 625 Waspaloy R-41 TABLE 15.7