Page 736 - Corrosion Engineering Principles and Practice

P. 736

688 C h a p t e r 1 5 H i g h - Te m p e r a t u r e C o r r o s i o n 689

in Cr or Al, whose oxides are stabilized by increasing O levels. Alloys,

2

which generally exhibit increased oxidation rates as the O

2

concentration increase, are S30400, S41000, and S44600 stainless steels

and 9Cr-1Mo, Incoloy DS, alloys 617, and 253MA. These alloys tend to

form poor oxide scales [2].

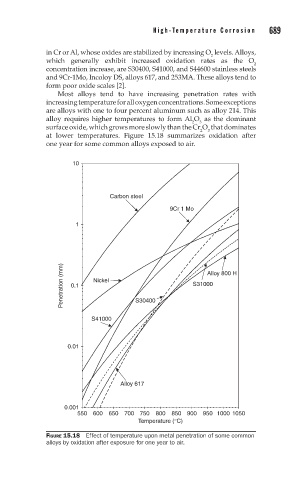

Most alloys tend to have increasing penetration rates with

increasing temperature for all oxygen concentrations. Some exceptions

are alloys with one to four percent aluminum such as alloy 214. This

alloy requires higher temperatures to form Al O as the dominant

3

2

surface oxide, which grows more slowly than the Cr O that dominates

2

3

at lower temperatures. Figure 15.18 summarizes oxidation after

one year for some common alloys exposed to air.

10

Carbon steel

9Cr 1 Mo

1

Penetration (mm) 0.1 Nickel S30400 S31000

Alloy 800 H

S41000

0.01

Alloy 617

0.001

550 600 650 700 750 800 850 900 950 1000 1050

Temperature (°C)

FIGURE 15.18 Effect of temperature upon metal penetration of some common

alloys by oxidation after exposure for one year to air.