Page 735 - Corrosion Engineering Principles and Practice

P. 735

688 C h a p t e r 1 5 H i g h - Te m p e r a t u r e C o r r o s i o n 689

The vapor aluminum-diffused surface layer is hard and brittle, but

the bulk substrate retains the properties of conventional steels.

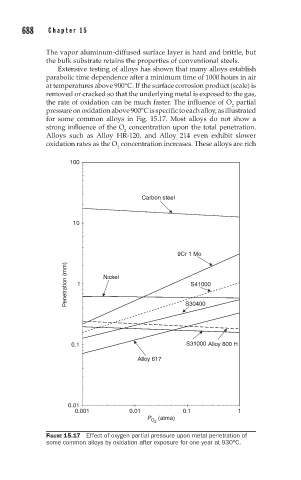

Extensive testing of alloys has shown that many alloys establish

parabolic time dependence after a minimum time of 1000 hours in air

at temperatures above 900°C. If the surface corrosion product (scale) is

removed or cracked so that the underlying metal is exposed to the gas,

the rate of oxidation can be much faster. The influence of O partial

2

pressure on oxidation above 900°C is specific to each alloy, as illustrated

for some common alloys in Fig. 15.17. Most alloys do not show a

strong influence of the O concentration upon the total penetration.

2

Alloys such as Alloy HR-120, and Alloy 214 even exhibit slower

oxidation rates as the O concentration increases. These alloys are rich

2

100

Carbon steel

10

9Cr 1 Mo

Penetration (mm) 1 Nickel S30400

S41000

0.1 S31000 Alloy 800 H

Alloy 617

0.01

0.001 0.01 0.1 1

(atma)

P O

2

FIGURE 15.17 Effect of oxygen partial pressure upon metal penetration of

some common alloys by oxidation after exposure for one year at 930°C.