Page 730 - Corrosion Engineering Principles and Practice

P. 730

682 C h a p t e r 1 5 H i g h - Te m p e r a t u r e C o r r o s i o n 683

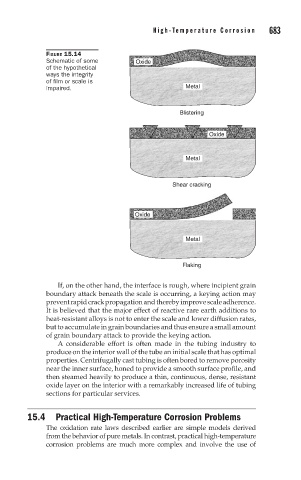

FIGURE 15.14

Schematic of some Oxide

of the hypothetical

ways the integrity

of film or scale is

impaired. Metal

Blistering

Oxide

Metal

Shear cracking

Oxide

Metal

Flaking

If, on the other hand, the interface is rough, where incipient grain

boundary attack beneath the scale is occurring, a keying action may

prevent rapid crack propagation and thereby improve scale adherence.

It is believed that the major effect of reactive rare earth additions to

heat-resistant alloys is not to enter the scale and lower diffusion rates,

but to accumulate in grain boundaries and thus ensure a small amount

of grain boundary attack to provide the keying action.

A considerable effort is often made in the tubing industry to

produce on the interior wall of the tube an initial scale that has optimal

properties. Centrifugally cast tubing is often bored to remove porosity

near the inner surface, honed to provide a smooth surface profile, and

then steamed heavily to produce a thin, continuous, dense, resistant

oxide layer on the interior with a remarkably increased life of tubing

sections for particular services.

15.4 Practical High-Temperature Corrosion Problems

The oxidation rate laws described earlier are simple models derived

from the behavior of pure metals. In contrast, practical high-temperature

corrosion problems are much more complex and involve the use of