Page 117 - Defrosting for Air Source Heat Pump

P. 117

Modeling study on uneven defrosting 109

90

Compressor Supply fan Indoor air

80

73.2 kJ

68.6 kJ

70 56.5 kJ

Heat supply for defrosting (kJ) 50 86.3% 86.3% 33.8 kJ 92.2%

60

40

30

20

1.0% 86.6%

10

1.0% 1.0% 1.1%

12.7% 12.5% 6.7%

0 12.4%

Experimental study Study Case 1 Study Case 2 Study Case 3

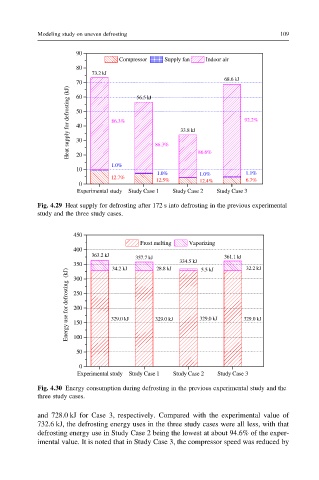

Fig. 4.29 Heat supply for defrosting after 172 s into defrosting in the previous experimental

study and the three study cases.

450

Frost melting Vaporizing

400

363.2 kJ

357.7 kJ 361.1 kJ

350 34.2 kJ 28.8 kJ 334.5 kJ 5.5 kJ 32.2 kJ

Energy use for defrosting (kJ) 250 329.0 kJ 329.0 kJ 329.0 kJ 329.0 kJ

300

200

150

100

50

0

Experimental study Study Case 1 Study Case 2 Study Case 3

Fig. 4.30 Energy consumption during defrosting in the previous experimental study and the

three study cases.

and 728.0 kJ for Case 3, respectively. Compared with the experimental value of

732.6 kJ, the defrosting energy uses in the three study cases were all less, with that

defrosting energy use in Study Case 2 being the lowest at about 94.6% of the exper-

imental value. It is noted that in Study Case 3, the compressor speed was reduced by