Page 116 - Defrosting for Air Source Heat Pump

P. 116

108 Defrosting for Air Source Heat Pump

28

Circuit 1 Circuit 2 Circuit 3

24

Tube surface temperature at exit ( o C) 16 8 T > T > T 3 187 s 1

20

T was decreasing.

2

1

12

172 s

0 4 95 s 179 s

80 100 120 140 160 180 200

Time (s)

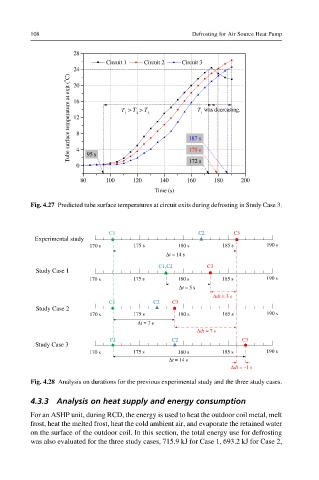

Fig. 4.27 Predicted tube surface temperatures at circuit exits during defrosting in Study Case 3.

C1 C2 C3

Experimental study

170 s 175 s 180 s 185 s 190 s

Δt = 14 s

C1,C2 C3

Study Case 1

170 s 175 s 180 s 185 s 190 s

Δt = 5 s

Δdt = 3 s

C1 C2 C3

Study Case 2

170 s 175 s 180 s 185 s 190 s

Δt = 7 s

Δdt = 7 s

C1 C2 C3

Study Case 3

170 s 175 s 180 s 185 s 190 s

Δt = 14 s

Δdt = –1 s

Fig. 4.28 Analysis on durations for the previous experimental study and the three study cases.

4.3.3 Analysis on heat supply and energy consumption

For an ASHP unit, during RCD, the energy is used to heat the outdoor coil metal, melt

frost, heat the melted frost, heat the cold ambient air, and evaporate the retained water

on the surface of the outdoor coil. In this section, the total energy use for defrosting

was also evaluated for the three study cases, 715.9 kJ for Case 1, 693.2 kJ for Case 2,