Page 177 - Defrosting for Air Source Heat Pump

P. 177

Frosting evenness coefficient 171

2.8

Case 1 Case 2 Case 3

2.4 T Case 3 > T Case 2 > T Case 1 T Case 1 > T Case 2 > T Case 3

Temperature of melted frost collected ( o C) 1.6 Temperature of surrounding air melted frost collected

2.0

1.2

Temperature of

0.8

0.4

0.0 135 s 145 s 150 s 187 s

0 30 60 90 120 150 180 210 240

Time (s)

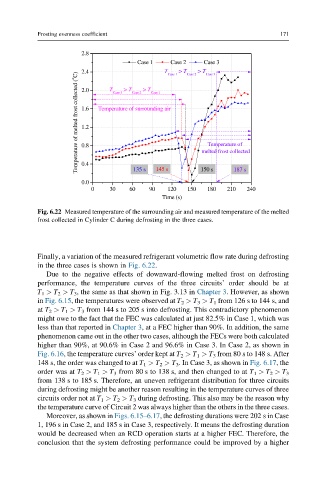

Fig. 6.22 Measured temperature of the surrounding air and measured temperature of the melted

frost collected in Cylinder C during defrosting in the three cases.

Finally, a variation of the measured refrigerant volumetric flow rate during defrosting

in the three cases is shown in Fig. 6.22.

Due to the negative effects of downward-flowing melted frost on defrosting

performance, the temperature curves of the three circuits’ order should be at

T 1 > T 2 > T 3 , the same as that shown in Fig. 3.13 in Chapter 3. However, as shown

in Fig. 6.15, the temperatures were observed at T 2 > T 3 > T 1 from 126 s to 144 s, and

at T 2 > T 1 > T 3 from 144 s to 205 s into defrosting. This contradictory phenomenon

might owe to the fact that the FEC was calculated at just 82.5% in Case 1, which was

less than that reported in Chapter 3, at a FEC higher than 90%. In addition, the same

phenomenon came out in the other two cases, although the FECs were both calculated

higher than 90%, at 90.6% in Case 2 and 96.6% in Case 3. In Case 2, as shown in

Fig. 6.16, the temperature curves’ order kept at T 2 > T 1 > T 3 from 80 s to 148 s. After

148 s, the order was changed to at T 1 > T 2 > T 3 . In Case 3, as shown in Fig. 6.17, the

order was at T 2 > T 1 > T 3 from 80 s to 138 s, and then changed to at T 1 > T 2 > T 3

from 138 s to 185 s. Therefore, an uneven refrigerant distribution for three circuits

during defrosting might be another reason resulting in the temperature curves of three

circuits order not at T 1 > T 2 > T 3 during defrosting. This also may be the reason why

the temperature curve of Circuit 2 was always higher than the others in the three cases.

Moreover, as shown in Figs. 6.15–6.17, the defrosting durations were 202 s in Case

1, 196 s in Case 2, and 185 s in Case 3, respectively. It means the defrosting duration

would be decreased when an RCD operation starts at a higher FEC. Therefore, the

conclusion that the system defrosting performance could be improved by a higher