Page 179 - Defrosting for Air Source Heat Pump

P. 179

Frosting evenness coefficient 173

frost coming from water-collecting Tray C. As shown in Fig. 6.22, at 187 s into

defrosting, the temperature curve order was observed at T 1 > T 2 > T 3 , although the

surrounding air temperature order was totally different at T 3 > T 2 > T 1 , as shown

in the first 140 s in Fig. 6.22. It could be concluded that the water temperature is

mainly decided by the heat transferred from the outdoor coil through the later warmer

melted frost flowing from the circuit to the tray and then to the cylinder. In addition,

the temperature curve order confirmed that less heat was taken from the outdoor coil

by melted frost for a higher FEC as a defrosting start for an ASHP unit. Therefore,

the negative effects of a lower FEC on the defrosting performance of an ASHP unit

with a multicircuit outdoor coil were further demonstrated.

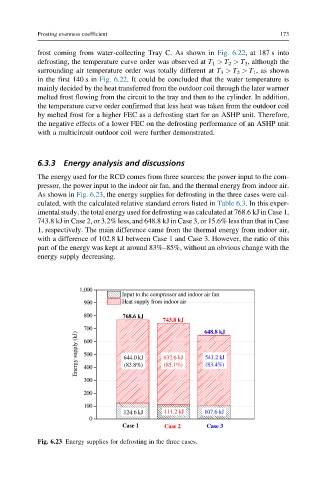

6.3.3 Energy analysis and discussions

The energy used for the RCD comes from three sources: the power input to the com-

pressor, the power input to the indoor air fan, and the thermal energy from indoor air.

As shown in Fig. 6.23, the energy supplies for defrosting in the three cases were cal-

culated, with the calculated relative standard errors listed in Table 6.3. In this exper-

imental study, the total energy used for defrosting was calculated at 768.6 kJ in Case 1,

743.8 kJ in Case 2, or 3.2% less, and 648.8 kJ in Case 3, or 15.6% less than that in Case

1, respectively. The main difference came from the thermal energy from indoor air,

with a difference of 102.8 kJ between Case 1 and Case 3. However, the ratio of this

part of the energy was kept at around 83%–85%, without an obvious change with the

energy supply decreasing.

1,000

Input to the compressor and indoor air fan

900 Heat supply from indoor air

800 768.6 kJ

743.8 kJ

700 648.8 kJ

Energy supply (kJ) 600 644.0 kJ 632.6 kJ 541.2 kJ

500

(83.8%)

(83.4%)

(85.1%)

400

300

200

100

124.6 kJ 111.2 kJ 107.6 kJ

0

Case 1 Case 2 Case 3

Fig. 6.23 Energy supplies for defrosting in the three cases.