Page 180 - Defrosting for Air Source Heat Pump

P. 180

174 Defrosting for Air Source Heat Pump

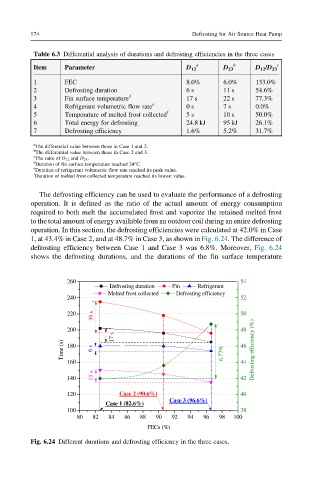

Table 6.3 Differential analysis of durations and defrosting efficiencies in the three cases

a b c

Item Parameter D 12 D 23 D 12 /D 23

1 FEC 8.0% 6.0% 133.0%

2 Defrosting duration 6 s 11 s 54.6%

3 Fin surface temperature d 17 s 22 s 77.3%

4 Refrigerant volumetric flow rate e 0 s 7 s 0.0%

5 Temperature of melted frost collected f 5 s 10 s 50.0%

6 Total energy for defrosting 24.8 kJ 95 kJ 26.1%

7 Defrosting efficiency 1.6% 5.2% 31.7%

a

The differential value between those in Case 1 and 2.

b

The differential value between those in Case 2 and 3.

c

The ratio of D 12 and D 23 .

d

Duration of fin surface temperature reached 24°C.

e

Duration of refrigerant volumetric flow rate reached its peak value.

f

Duration of melted frost collected temperature reached its lowest value.

The defrosting efficiency can be used to evaluate the performance of a defrosting

operation. It is defined as the ratio of the actual amount of energy consumption

required to both melt the accumulated frost and vaporize the retained melted frost

to the total amount of energy available from an outdoor coil during an entire defrosting

operation. In this section, the defrosting efficiencies were calculated at 42.0% in Case

1, at 43.4% in Case 2, and at 48.7% in Case 3, as shown in Fig. 6.24. The difference of

defrosting efficiency between Case 1 and Case 3 was 6.8%. Moreover, Fig. 6.24

shows the defrosting durations, and the durations of the fin surface temperature

260 54

Defrosting duration Fin Refrigerant

Melted frost collected Defrosting efficiency

240 52

220 50

39 s

200 48

17 s

Time (s) 180 6 s 6.77% 46 Defrosting efficiency (%)

160 44

15 s

140 42

120 Case 2 (90.6%) 40

Case 3 (96.6%)

Case 1 (82.6%)

100 38

80 82 84 86 88 90 92 94 96 98 100

FECs (%)

Fig. 6.24 Different durations and defrosting efficiency in the three cases.