Page 225 - Defrosting for Air Source Heat Pump

P. 225

The influence of refrigerant distribution on defrosting 219

supply for defrosting could save 98.9 kJ, and the defrosting efficiency could be

improved by 7.4% (from 40.5% to 47.9%), or at a ratio of 18.3%, when the refrigerant

is evenly distributed. (4) As analyzed, it could be speculated that the defrosting dura-

tions of the tube and fin could be used to compare the defrosting performances for

different defrosting systems. The peak value of TDOEE difference as well as their

duration difference could also be considered comprehensively as a defrosting evalu-

ation parameter.

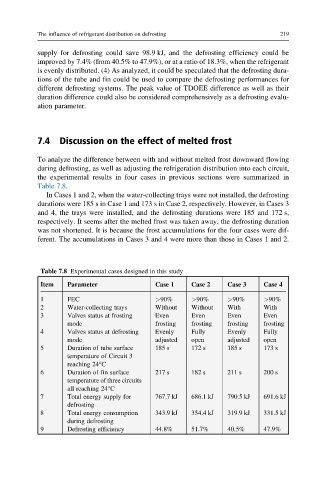

7.4 Discussion on the effect of melted frost

To analyze the difference between with and without melted frost downward flowing

during defrosting, as well as adjusting the refrigeration distribution into each circuit,

the experimental results in four cases in previous sections were summarized in

Table 7.8.

In Cases 1 and 2, when the water-collecting trays were not installed, the defrosting

durations were 185 s in Case 1 and 173 s in Case 2, respectively. However, in Cases 3

and 4, the trays were installed, and the defrosting durations were 185 and 172 s,

respectively. It seems after the melted frost was taken away, the defrosting duration

was not shortened. It is because the frost accumulations for the four cases were dif-

ferent. The accumulations in Cases 3 and 4 were more than those in Cases 1 and 2.

Table 7.8 Experimental cases designed in this study

Item Parameter Case 1 Case 2 Case 3 Case 4

1 FEC >90% >90% >90% >90%

2 Water-collecting trays Without Without With With

3 Valves status at frosting Even Even Even Even

mode frosting frosting frosting frosting

4 Valves status at defrosting Evenly Fully Evenly Fully

mode adjusted open adjusted open

5 Duration of tube surface 185 s 172 s 185 s 173 s

temperature of Circuit 3

reaching 24°C

6 Duration of fin surface 217 s 182 s 211 s 200 s

temperature of three circuits

all reaching 24°C

7 Total energy supply for 767.7 kJ 686.1 kJ 790.5 kJ 691.6 kJ

defrosting

8 Total energy consumption 343.9 kJ 354.4 kJ 319.9 kJ 331.5 kJ

during defrosting

9 Defrosting efficiency 44.8% 51.7% 40.5% 47.9%