Page 222 - Defrosting for Air Source Heat Pump

P. 222

216 Defrosting for Air Source Heat Pump

7

Case 1

6

Case 2

5

Temperature ( o C) 4 3 T > T 2 T > T 1

1

2

T T T > T

2 1 2 2 1

90 s

1 60 s

26 s

0 40 80 120 160 200 240 280

Time (s)

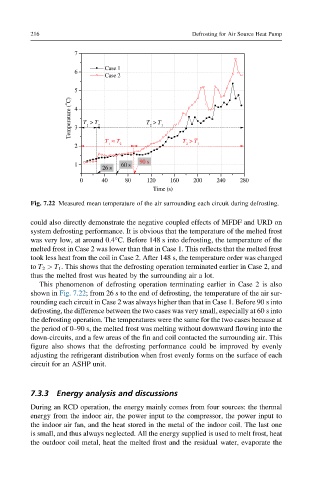

Fig. 7.22 Measured mean temperature of the air surrounding each circuit during defrosting.

could also directly demonstrate the negative coupled effects of MFDF and URD on

system defrosting performance. It is obvious that the temperature of the melted frost

was very low, at around 0.4°C. Before 148 s into defrosting, the temperature of the

melted frost in Case 2 was lower than that in Case 1. This reflects that the melted frost

took less heat from the coil in Case 2. After 148 s, the temperature order was changed

to T 2 > T 1 . This shows that the defrosting operation terminated earlier in Case 2, and

thus the melted frost was heated by the surrounding air a lot.

This phenomenon of defrosting operation terminating earlier in Case 2 is also

shown in Fig. 7.22; from 26 s to the end of defrosting, the temperature of the air sur-

rounding each circuit in Case 2 was always higher than that in Case 1. Before 90 s into

defrosting, the difference between the two cases was very small, especially at 60 s into

the defrosting operation. The temperatures were the same for the two cases because at

the period of 0–90 s, the melted frost was melting without downward flowing into the

down-circuits, and a few areas of the fin and coil contacted the surrounding air. This

figure also shows that the defrosting performance could be improved by evenly

adjusting the refrigerant distribution when frost evenly forms on the surface of each

circuit for an ASHP unit.

7.3.3 Energy analysis and discussions

During an RCD operation, the energy mainly comes from four sources: the thermal

energy from the indoor air, the power input to the compressor, the power input to

the indoor air fan, and the heat stored in the metal of the indoor coil. The last one

is small, and thus always neglected. All the energy supplied is used to melt frost, heat

the outdoor coil metal, heat the melted frost and the residual water, evaporate the