Page 338 - Defrosting for Air Source Heat Pump

P. 338

Technoeconomic performances 333

90

Electricity cost on defrosting

Indoor air thermal energy consumed

80

) 75.80

Y 70

N

C 29.53

(

t

s

o 60 63.82

c

g

n

i 12.83

n 56.81 49.06

n

u 50

R 46.28

48.86

40 44.36 43.99

30

Case D5 Case D6 Case D7 Case D8

Four typical cases

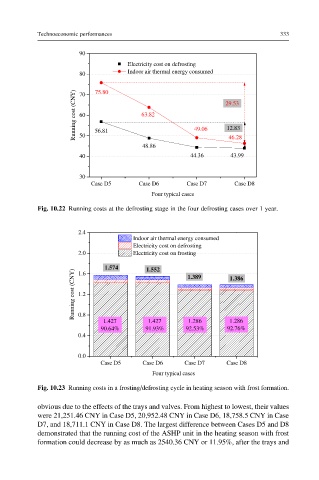

Fig. 10.22 Running costs at the defrosting stage in the four defrosting cases over 1 year.

2.4

Indoor air thermal energy consumed

Electricity cost on defrosting

2.0 Electricity cost on frosting

1.574

) 1.552

Y 1.6

N 1.389 1.386

C

(

t

s

o 1.2

c

g

n

i

n

n

u 0.8

R

1.427 1.427 1.286 1.286

90.64% 91.93% 92.53% 92.76%

0.4

0.0

Case D5 Case D6 Case D7 Case D8

Four typical cases

Fig. 10.23 Running costs in a frosting/defrosting cycle in heating season with frost formation.

obvious due to the effects of the trays and valves. From highest to lowest, their values

were 21,251.46 CNY in Case D5, 20,952.48 CNY in Case D6, 18,758.5 CNY in Case

D7, and 18,711.1 CNY in Case D8. The largest difference between Cases D5 and D8

demonstrated that the running cost of the ASHP unit in the heating season with frost

formation could decrease by as much as 2540.36 CNY or 11.95%, after the trays and