Page 335 - Defrosting for Air Source Heat Pump

P. 335

330 Defrosting for Air Source Heat Pump

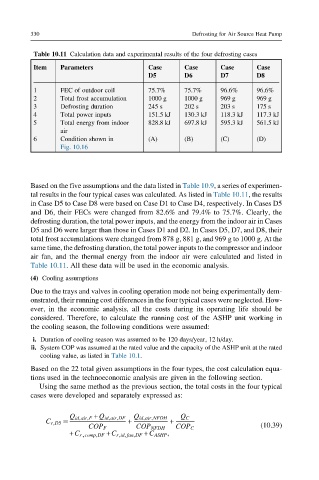

Table 10.11 Calculation data and experimental results of the four defrosting cases

Item Parameters Case Case Case Case

D5 D6 D7 D8

1 FEC of outdoor coil 75.7% 75.7% 96.6% 96.6%

2 Total frost accumulation 1000 g 1000 g 969 g 969 g

3 Defrosting duration 245 s 202 s 203 s 175 s

4 Total power inputs 151.5 kJ 130.3 kJ 118.3 kJ 117.3 kJ

5 Total energy from indoor 828.8 kJ 697.8 kJ 595.3 kJ 561.5 kJ

air

6 Condition shown in (A) (B) (C) (D)

Fig. 10.16

Based on the five assumptions and the data listed in Table 10.9, a series of experimen-

tal results in the four typical cases was calculated. As listed in Table 10.11, the results

in Case D5 to Case D8 were based on Case D1 to Case D4, respectively. In Cases D5

and D6, their FECs were changed from 82.6% and 79.4% to 75.7%. Clearly, the

defrosting duration, the total power inputs, and the energy from the indoor air in Cases

D5 and D6 were larger than those in Cases D1 and D2. In Cases D5, D7, and D8, their

total frost accumulations were changed from 878 g, 881 g, and 969 g to 1000 g. At the

same time, the defrosting duration, the total power inputs to the compressor and indoor

air fan, and the thermal energy from the indoor air were calculated and listed in

Table 10.11. All these data will be used in the economic analysis.

(4) Cooling assumptions

Due to the trays and valves in cooling operation mode not being experimentally dem-

onstrated, their running cost differences in the four typical cases were neglected. How-

ever, in the economic analysis, all the costs during its operating life should be

considered. Therefore, to calculate the running cost of the ASHP unit working in

the cooling season, the following conditions were assumed:

i. Duration of cooling season was assumed to be 120 days/year, 12 h/day.

ii. System COP was assumed at the rated value and the capacity of the ASHP unit at the rated

cooling value, as listed in Table 10.1.

Based on the 22 total given assumptions in the four types, the cost calculation equa-

tions used in the technoeconomic analysis are given in the following section.

Using the same method as the previous section, the total costs in the four typical

cases were developed and separately expressed as:

Q id,air,F + Q id,air,DF Q id,air,NFDH Q C

C r,D5 ¼ + +

COP F COP NFDH COP C (10.39)

+ C r,comp,DF + C r,id, fan,DF + C ASHP ,