Page 251 - Design for Environment A Guide to Sustainable Product Development

P. 251

Electr onic Equipment Industries 227

reusing 70–90% of machine components (by weight), while meeting

performance specifications for equipment with parts that are all new.

Xerox also designs product families around modular product archi-

tectures and a common set of core components.

Thanks to these advances, a returned machine can be rebuilt as

the same model through remanufacture, converted to a new model

within the same product family, or used as a source of parts for next-

generation models. Improved forecasting of equipment returns has

allowed Xerox to rely on previous generations of equipment as a

source of components for products in development. A Xerox product

whose designs are based on previous models may have 60% of its

parts in common with previous equipment. The practice of reusing

parts reduces the amount of raw material needed to manufacture

new parts, which generates several hundred million dollars in cost

savings each year. Moreover, energy savings are significant; in 2006,

energy savings from reused parts totaled six million therms (170,000

megawatt hours)—enough energy to light more than 136,000 U.S.

homes for a year.

These capabilities have made it easy for Xerox to comply with the

various country programs that implement the European Union’s

Waste Electrical and Electronic Equipment (WEEE) directive (see

Chapter 3). The annual amount of waste diverted from landfill has

declined since 2002, in part due to lighter-weight machines (see Fig-

ure 11.3). In addition, the number of office machines returned for

remanufacturing has decreased since the WEEE legislation mandates

the national collection and recycling of scrap office products.

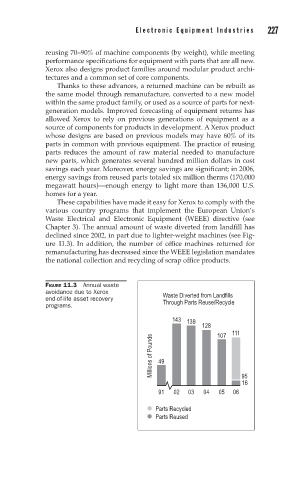

FIGURE 11.3 Annual waste

avoidance due to Xerox

end-of-life asset recovery Waste Diverted from Landfills

programs. Through Parts Reuse/Recycle

143 139

128

111

107

Millions of Pounds 49

95

16

91 02 03 04 05 06

Parts Recycled

Parts Reused