Page 428 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 428

386 Chapter Ten

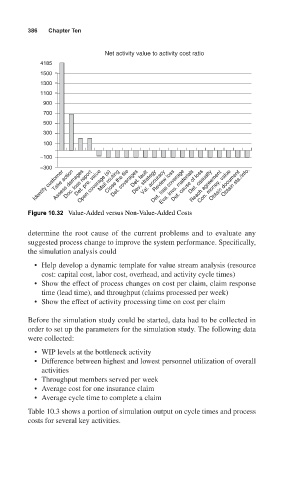

Net activity value to activity cost ratio

4185

1500

1300

1100

900

700

500

300

100

−100

−300

Obtain sta./info.

Close the file

Dev. strategy

Det. coverages

Assess damages

Det. pre. value

Open coverage (s)

Take action

Det. loss coverage

Det. cause of loss

Review loss

Identify customer Doc. loss report Mail routing Det. fault Val. accuracy Eva. invs. materials Det. casualty Obtain document

Con. money. value

Reach agreement

Figure 10.32 Value-Added versus Non-Value-Added Costs

determine the root cause of the current problems and to evaluate any

suggested process change to improve the system performance. Specifically,

the simulation analysis could

• Help develop a dynamic template for value stream analysis (resource

cost: capital cost, labor cost, overhead, and activity cycle times)

• Show the effect of process changes on cost per claim, claim response

time (lead time), and throughput (claims processed per week)

• Show the effect of activity processing time on cost per claim

Before the simulation study could be started, data had to be collected in

order to set up the parameters for the simulation study. The following data

were collected:

• WIP levels at the bottleneck activity

• Difference between highest and lowest personnel utilization of overall

activities

• Throughput members served per week

• Average cost for one insurance claim

• Average cycle time to complete a claim

Table 10.3 shows a portion of simulation output on cycle times and process

costs for several key activities.