Page 290 - Design of Simple and Robust Process Plants

P. 290

276 Chapter 7 Optimization of an Integrated Complex of Process Plants

Butenes

Transport Cracker Butadiene Poly butadiene

H2

SB latex

EB /Styrene Poly styrene

Benzene

Cyclo hexane

C5

C7

C8

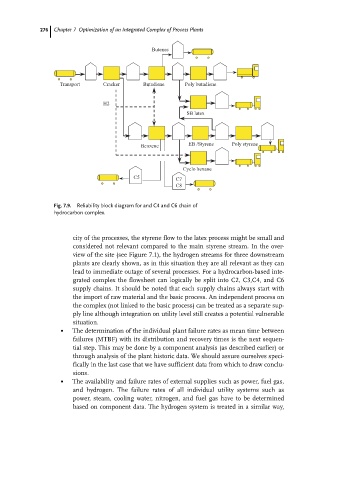

Fig. 7.9. Reliability block diagram for and C4 and C6 chain of

hydrocarbon complex.

city of the processes, the styrene flow to the latex process might be small and

considered not relevant compared to the main styrene stream. In the over-

view of the site (see Figure 7.1), the hydrogen streams for three downstream

plants are clearly shown, as in this situation they are all relevant as they can

lead to immediate outage of several processes. For a hydrocarbon-based inte-

grated complex the flowsheet can logically be split into C2, C3,C4, and C6

supply chains. It should be noted that each supply chains always start with

the import of raw material and the basic process. An independent process on

the complex (not linked to the basic process) can be treated as a separate sup-

ply line although integration on utility level still creates a potential vulnerable

situation.

. The determination of the individual plant failure rates as mean time between

failures (MTBF) with its distribution and recovery times is the next sequen-

tial step. This may be done by a component analysis (as described earlier) or

through analysis of the plant historic data. We should assure ourselves speci-

fically in the last case that we have sufficient data from which to draw conclu-

sions.

. The availability and failure rates of external supplies such as power, fuel gas,

and hydrogen. The failure rates of all individual utility systems such as

power, steam, cooling water, nitrogen, and fuel gas have to be determined

based on component data. The hydrogen system is treated in a similar way,