Page 200 - Electric Drives and Electromechanical Systems

P. 200

Chapter 7 Induction motors 195

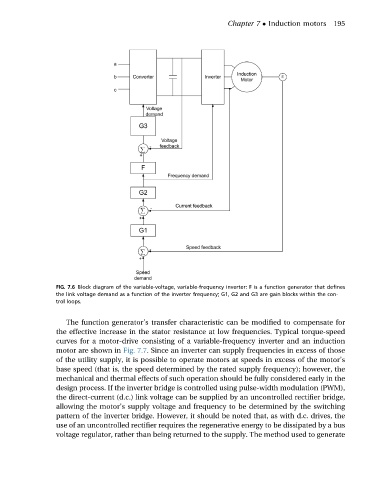

FIG. 7.6 Block diagram of the variable-voltage, variable-frequency inverter: F is a function generator that defines

the link voltage demand as a function of the inverter frequency; G1, G2 and G3 are gain blocks within the con-

trol loops.

The function generator’s transfer characteristic can be modified to compensate for

the effective increase in the stator resistance at low frequencies. Typical torque-speed

curves for a motor-drive consisting of a variable-frequency inverter and an induction

motor are shown in Fig. 7.7. Since an inverter can supply frequencies in excess of those

of the utility supply, it is possible to operate motors at speeds in excess of the motor’s

base speed (that is, the speed determined by the rated supply frequency); however, the

mechanical and thermal effects of such operation should be fully considered early in the

design process. If the inverter bridge is controlled using pulse-width modulation (PWM),

the direct-current (d.c.) link voltage can be supplied by an uncontrolled rectifier bridge,

allowing the motor’s supply voltage and frequency to be determined by the switching

pattern of the inverter bridge. However, it should be noted that, as with d.c. drives, the

use of an uncontrolled rectifier requires the regenerative energy to be dissipated by a bus

voltage regulator, rather than being returned to the supply. The method used to generate