Page 111 - Electromechanical Devices and Components Illustrated Sourcebook

P. 111

Chapter 4 Electrical Controls 73

Fired Filler

Ceramic

Housing

Schematic Symbol

Carbon

Plastic Case

Electrodes

Leads

Bare Wire

Figure 4-109 High-Wattage Ceramic Resistor

Figure 4-107 Carbon Resistor

Screw Lug

Aluminum Case

2%, 5%, & 10%

Solder Terminal

Five Band

Top View

Cooling Fins

Color 1st Band 2nd Band 3rd Band Multiplier Tolerance

Black 1 1 1 1 1%

Side View End View

Brown 2 2 2 10 2%

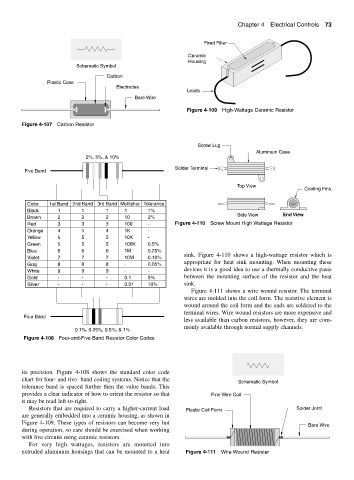

Red 3 3 3 100 - Figure 4-110 Screw Mount High Wattage Resistor

Orange 4 4 4 1K -

Yellow 5 5 5 10K -

Green 5 5 5 100K 0.5%

Blue 6 6 6 1M 0.25%

sink. Figure 4-110 shows a high-wattage resistor which is

Violet 7 7 7 10M 0.10%

appropriate for heat sink mounting. When mounting these

Gray 8 8 8 - 0.05%

devices it is a good idea to use a thermally conductive paste

White 9 9 9 - -

Gold - - - 0.1 5% between the mounting surface of the resistor and the heat

Silver - - - 0.01 10% sink.

Figure 4-111 shows a wire wound resistor. The terminal

wires are molded into the coil form. The resistive element is

wound around the coil form and the ends are soldered to the

terminal wires. Wire wound resistors are more expensive and

Four Band

less available than carbon resistors, however, they are com-

monly available through normal supply channels.

0.1%, 0.25%, 0.5%, & 1%

Figure 4-108 Four-and-Five Band Resistor Color Codes

its precision. Figure 4-108 shows the standard color code

chart for four- and five- band coding systems. Notice that the

Schematic Symbol

tolerance band is spaced further then the value bands. This

provides a clear indicator of how to orient the resistor so that Fine Wire Coil

it may be read left-to-right.

Resistors that are required to carry a higher-current load Plastic Coil Form Solder Joint

are generally embedded into a ceramic housing, as shown in

Figure 4-109. These types of resistors can become very hot

Bare Wire

during operation, so care should be exercised when working

with live circuits using ceramic resistors.

For very high wattages, resistors are mounted into

extruded aluminum housings that can be mounted to a heat Figure 4-111 Wire Wound Resister