Page 144 - Electromechanical Devices and Components Illustrated Sourcebook

P. 144

106 Electromechanical Devices & Components Illustrated Sourcebook

One of the most important divisions in electromechanics is

rotating equipment. The two most noteworthy pieces of rotat-

ing equipment are the motor and the generator. We encoun- M

tered electric motors virtually everywhere we go. Our

kitchens have a variety of motors inside the appliances that

dot our countertops and cabinets. Our automobiles use elec- Schematic Symbol

tric motors to drive the windshield wipers, heater fan, power

windows, automatic doors, and fuel pumps. Every time we

ride an elevator we experience the work generated by an elec-

tric motor. The air-conditioning and heat we enjoy would not

be possible without the motors that drive the air handlers and

compressors within the systems. Permanet

The electric motors that make our lives so comfortable must Magnet

have a ready source of power; this is where generators come Rotor Pole

into play. Although most of us do not encounter generators in Rotor Core

our day-to-day lives, they are closer than you might think. All Armature

Rotor Coil

of the electric power that you rely on at home and work is pro-

duced by generators. Most people take their access to reliable Brush

electric power for granted and never really consider where it Axle

comes from or how it’s produced. Even the common terms that N S

are associated with power generation like coal, hydroelectric,

and nuclear have no real meaning to the average person. Brush Spring Magnet Pole

Probably the closest generator to most people is the alterna- Terminal

tor in their automobile. Without this critical piece of equipment,

the electrical system of your car would quickly fail. Many of us Figure 6-1 Permanent Magnet DC Motor

have experienced a failed alternator while driving. When the

alternator stops producing power, the car’s electrical system

starts to operate on the battery alone. It doesn’t take long before

the load depletes the battery and the car shuts down.

Permanent

Magnet

Permanent Magnet DC Motors

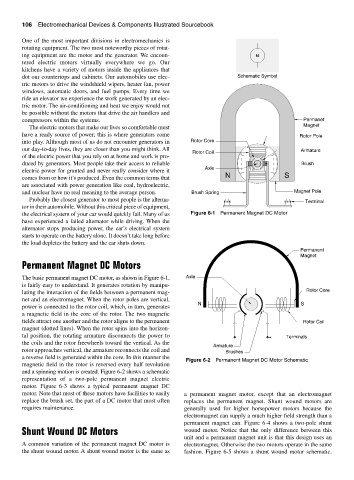

The basic permanent magnet DC motor, as shown in Figure 6-1, Axle

is fairly easy to understand. It generates rotation by manipu-

lating the interaction of the fields between a permanent mag- Rotor Core

net and an electromagnet. When the rotor poles are vertical,

N S

power is connected to the rotor coil, which, in turn, generates

a magnetic field in the core of the rotor. The two magnetic

fields attract one another and the rotor aligns to the permanent Rotor Coil

magnet (dotted lines). When the rotor spins into the horizon-

tal position, the rotating armature disconnects the power to Terminals

the coils and the rotor freewheels toward the vertical. As the

Armature

rotor approaches vertical, the armature reconnects the coil and Brushes

a reverse field is generated within the core. In this manner the

Figure 6-2 Permanent Magnet DC Motor Schematic

magnetic field in the rotor is reversed every half revolution

and a spinning motion is created. Figure 6-2 shows a schematic

representation of a two-pole permanent magnet electric

motor. Figure 6-3 shows a typical permanent magnet DC

motor. Note that most of these motors have facilities to easily a permanent magnet motor, except that an electromagnet

replace the brush set, the part of a DC motor that most often replaces the permanent magnet. Shunt wound motors are

requires maintenance. generally used for higher horsepower motors because the

electromagnet can supply a much higher field strength than a

permanent magnet can. Figure 6-4 shows a two-pole shunt

Shunt Wound DC Motors wound motor. Notice that the only difference between this

unit and a permanent magnet unit is that this design uses an

A common variation of the permanent magnet DC motor is electromagnet. Otherwise the two motors operate in the same

the shunt wound motor. A shunt wound motor is the same as fashion. Figure 6-5 shows a shunt wound motor schematic.