Page 148 - Electromechanical Devices and Components Illustrated Sourcebook

P. 148

110 Electromechanical Devices & Components Illustrated Sourcebook

motors are supplied on what is termed a resilient mount. Start Capacitor Centrifugal Switch

These mounts are specifically designed to minimize noise

and vibration.

Run Capacitor

Split Capacitor Motors

AC Power

Split capacitor motors are similar in design to a capacitor start Rotor

motor, except that the centrifugal switch is eliminated from Run Winding

the assembly. The start winding is connected to the power

source through a capacitor and is designed to be continuously

energized. This sets up a continuous asymmetry in the field

Start Winding

and, therefore, the power of the start winding must be mini-

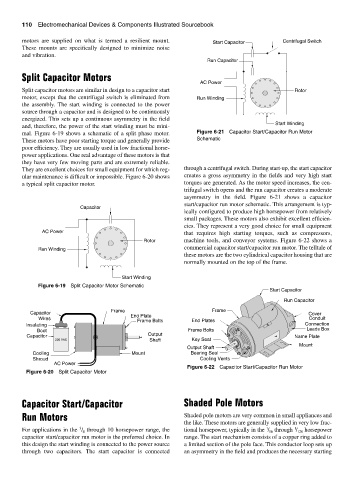

mal. Figure 6-19 shows a schematic of a split phase motor. Figure 6-21 Capacitor Start/Capacitor Run Motor

These motors have poor starting torque and generally provide Schematic

poor efficiency. They are usually used in low fractional horse-

power applications. One real advantage of these motors is that

they have very few moving parts and are extremely reliable.

They are excellent choices for small equipment for which reg- through a centrifugal switch. During start-up, the start capacitor

ular maintenance is difficult or impossible. Figure 6-20 shows creates a gross asymmetry in the fields and very high start

a typical split capacitor motor. torques are generated. As the motor speed increases, the cen-

trifugal switch opens and the run capacitor creates a moderate

asymmetry in the field. Figure 6-21 shows a capacitor

start/capacitor run motor schematic. This arrangement is typ-

Capacitor

ically configured to produce high horsepower from relatively

small packages. These motors also exhibit excellent efficien-

cies. They represent a very good choice for small equipment

AC Power that requires high starting torques, such as compressors,

Rotor machine tools, and conveyor systems. Figure 6-22 shows a

commercial capacitor start/capacitor run motor. The telltale of

Run Winding

these motors are the two cylindrical capacitor housing that are

normally mounted on the top of the frame.

Start Winding

Figure 6-19 Split Capacitor Motor Schematic

Start Capacitor

Run Capacitor

Capacitor Frame End Plate Frame Cover

Wires Frame Bolts End Plates Conduit

Insulating Connection

Boot Frame Bolts Leads Box

Capacitor Output Name Plate

220 VAC Shaft Key Seat

Mount

Output Shaft

Cooling Mount Bearing Seal

Shroud Cooling Vents

AC Power

Figure 6-22 Capacitor Start/Capacitor Run Motor

Figure 6-20 Split Capacitor Motor

Capacitor Start/Capacitor Shaded Pole Motors

Run Motors Shaded pole motors are very common in small appliances and

the like. These motors are generally supplied in very low frac-

1

3

1

For applications in the / through 10 horsepower range, the tional horsepower, typically in the / through / 120 horsepower

4

16

capacitor start/capacitor run motor is the preferred choice. In range. The start mechanism consists of a copper ring added to

this design the start winding is connected to the power source a limited section of the pole face. This conductor loop sets up

through two capacitors. The start capacitor is connected an asymmetry in the field and produces the necessary starting