Page 147 - Electromechanical Devices and Components Illustrated Sourcebook

P. 147

Chapter 6 Rotating Components 109

Bearing Conductors Capacitor Housing

Frame

Shaft End Ring Nameplate

End Plate Rotor

Frame

Bolts

Output

Laminations Shaft

End Ring

Conductors

Figure 6-14 Squirrel Cage Rotor

Mount

AC Cord

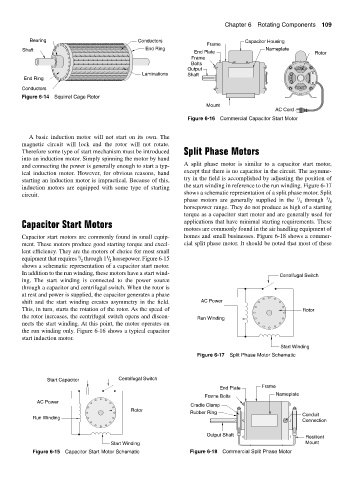

Figure 6-16 Commercial Capacitor Start Motor

A basic induction motor will not start on its own. The

magnetic circuit will lock and the rotor will not rotate.

Therefore some type of start mechanism must be introduced Split Phase Motors

into an induction motor. Simply spinning the motor by hand

A split phase motor is similar to a capacitor start motor,

and connecting the power is generally enough to start a typ-

except that there is no capacitor in the circuit. The asymme-

ical induction motor. However, for obvious reasons, hand

try in the field is accomplished by adjusting the position of

starting an induction motor is impractical. Because of this,

the start winding in reference to the run winding. Figure 6-17

induction motors are equipped with some type of starting

shows a schematic representation of a split phase motor. Split

circuit.

1 3

phase motors are generally supplied in the / 4 through / 4

horsepower range. They do not produce as high of a starting

torque as a capacitor start motor and are generally used for

Capacitor Start Motors applications that have minimal starting requirements. These

motors are commonly found in the air handling equipment of

Capacitor start motors are commonly found in small equip- homes and small businesses. Figure 6-18 shows a commer-

ment. These motors produce good starting torque and excel- cial split phase motor. It should be noted that most of these

lent efficiency. They are the motors of choice for most small

1

1

equipment that requires / through 1 / horsepower. Figure 6-15

2

2

shows a schematic representation of a capacitor start motor.

In addition to the run winding, these motors have a start wind- Centrifugal Switch

ing. The start winding is connected to the power source

through a capacitor and centrifugal switch. When the rotor is

at rest and power is supplied, the capacitor generates a phase

shift and the start winding creates asymmetry in the field. AC Power

This, in turn, starts the rotation of the rotor. As the speed of Rotor

the rotor increases, the centrifugal switch opens and discon- Run Winding

nects the start winding. At this point, the motor operates on

the run winding only. Figure 6-16 shows a typical capacitor

start induction motor.

Start Winding

Figure 6-17 Split Phase Motor Schematic

Start Capacitor Centrifugal Switch

End Plate Frame

Nameplate

Frame Bolts

AC Power

Cradle Clamp

Rotor

Rubber Ring Conduit

Run Winding

Connection

Output Shaft Resilient

Start Winding Mount

Figure 6-15 Capacitor Start Motor Schematic Figure 6-18 Commercial Split Phase Motor