Page 145 - Electromechanical Devices and Components Illustrated Sourcebook

P. 145

Chapter 6 Rotating Components 107

M M

Schematic Symbol

Schematic Symbol

Field Terminals

Terminals Frame Armature Frame

Terminals

Brushes Output

Shaft

Brushes Output Shaft

Shunt Coil

Screws

Magnet

Mount

Screws

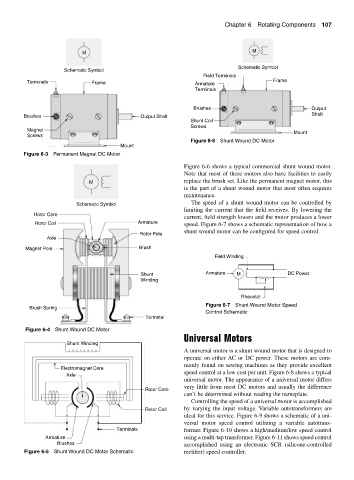

Figure 6-6 Shunt Wound DC Motor

Mount

Figure 6-3 Permanent Magnet DC Motor

Figure 6-6 shows a typical commercial shunt wound motor.

Note that most of these motors also have facilities to easily

M replace the brush set. Like the permanent magnet motor, this

is the part of a shunt wound motor that most often requires

maintenance.

The speed of a shunt wound motor can be controlled by

Schematic Symbol

limiting the current that the field receives. By lowering the

Rotor Core

current, field strength lowers and the motor produces a lower

Rotor Coil Armature speed. Figure 6-7 shows a schematic representation of how a

shunt wound motor can be configured for speed control.

Rotor Pole

Axle

Magnet Pole Brush

Field Winding

Shunt Armature M DC Power

Winding

Rheostat

Figure 6-7 Shunt Wound Motor Speed

Brush Spring

Control Schematic

Terminal

Figure 6-4 Shunt Wound DC Motor

Universal Motors

Shunt Winding

A universal motor is a shunt wound motor that is designed to

operate on either AC or DC power. These motors are com-

monly found on sewing machines as they provide excellent

Electromagnet Core

speed control at a low cost per unit. Figure 6-8 shows a typical

Axle

universal motor. The appearance of a universal motor differs

very little from most DC motors and usually the difference

Rotor Core

can’t be determined without reading the nameplate.

Controlling the speed of a universal motor is accomplished

Rotor Coil by varying the input voltage. Variable autotransformers are

ideal for this service. Figure 6-9 shows a schematic of a uni-

versal motor speed control utilizing a variable autotrans-

Terminals former. Figure 6-10 shows a high/medium/low speed control

Armature using a multi-tap transformer. Figure 6-11 shows speed control

Brushes accomplished using an electronic SCR (silicone-controlled

Figure 6-5 Shunt Wound DC Motor Schematic rectifier) speed controller.