Page 298 - Electromechanical Devices and Components Illustrated Sourcebook

P. 298

260 Electromechanical Devices & Components Illustrated Sourcebook

Fixed Pivot which also drives the gauge needle. As pressure is applied to

Terminals the unit, the Borden tube tries to straighten out and activates

Pressure the gear mechanism that turns the needle and potentiometer.

Housing

Resistive The output of the potentiometer can drive either a voltage

Element divider or a Wheatstone bridge.

Lever Arm For more sensitive pressure readings, a bellows pressure

Pressure transducer is generally specified, as shown in Figure 15-48.

Port Wiper

Pressure is fed to the input and the bellows extends. The

opposite end of the bellows is connected to a linear poten-

Cam tiometer. As the pressure varies, so does the bellow’s length

and the position of the potentiometer. The output of the poten-

Diaphragm

tiometer can drive either a voltage divider or a Wheatstone

Figure 15-45 Diaphragm Pressure Transducer bridge.

Potentiometer

Gauge Housing Terminals Bellows Plunger Rod

Linear

Input Head

Potentiometer

Pressure

Needle 80 100 120

60 140 Input

Bezel 40 160

20 180 Bellows Weld

PSI 200 A B C Terminals

Moving Head

USA

Figure 15-48 Bellows Pressure Transducer

NPT Thread

Input

Figure 15-46 Commercial Pressure Gauge with 0- to 10-Volt

Output

A bellows-type pressure transducer can be constructed

using a spring return cylinder, as shown in Figure 15-49. The

output shaft of the cylinder is connected to the shaft of a lin-

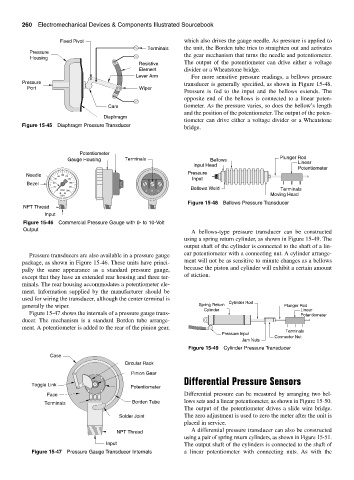

Pressure transducers are also available in a pressure gauge ear potentiometer with a connecting nut. A cylinder arrange-

package, as shown in Figure 15-46. These units have princi- ment will not be as sensitive to minute changes as a bellows

pally the same appearance as a standard pressure gauge, because the piston and cylinder will exhibit a certain amount

except that they have an extended rear housing and three ter- of stiction.

minals. The rear housing accommodates a potentiometer ele-

ment. Information supplied by the manufacturer should be

used for wiring the transducer, although the center terminal is

Cylinder Rod

generally the wiper. Spring Return Plunger Rod

Cylinder Linear

Figure 15-47 shows the internals of a pressure gauge trans- Potentiometer

ducer. The mechanism is a standard Borden tube arrange-

ment. A potentiometer is added to the rear of the pinion gear,

Terminals

Pressure Input

Connector Nut

Jam Nuts

Figure 15-49 Cylinder Pressure Transducer

Case

Circular Rack

Pinion Gear

Differential Pressure Sensors

Toggle Link

Potentiometer

Face Differential pressure can be measured by arranging two bel-

Terminals Borden Tube lows sets and a linear potentiometer, as shown in Figure 15-50.

The output of the potentiometer drives a slide wire bridge.

Solder Joint The zero adjustment is used to zero the meter after the unit is

placed in service.

A differential pressure transducer can also be constructed

NPT Thread

using a pair of spring return cylinders, as shown in Figure 15-51.

Input The output shaft of the cylinders is connected to the shaft of

Figure 15-47 Pressure Gauge Transducer Internals a linear potentiometer with connecting nuts. As with the