Page 302 - Electromechanical Devices and Components Illustrated Sourcebook

P. 302

264 Electromechanical Devices & Components Illustrated Sourcebook

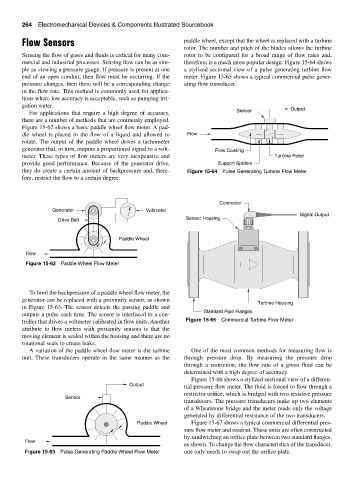

Flow Sensors paddle wheel, except that the wheel is replaced with a turbine

rotor. The number and pitch of the blades allows the turbine

Sensing the flow of gases and fluids is critical for many com- rotor to be configured for a broad range of flow rates and,

mercial and industrial processes. Sensing flow can be as sim- therefore, is a much more popular design. Figure 15-64 shows

ple as viewing a pressure gauge. If pressure is present at one a stylized sectional view of a pulse generating turbine flow

end of an open conduit, then flow must be occurring. If the meter. Figure 15-65 shows a typical commercial pulse gener-

pressure changes, then there will be a corresponding change ating flow transducer.

in the flow rate. This method is commonly used for applica-

tions where low accuracy is acceptable, such as pumping irri-

gation water. Output

For applications that require a high degree of accuracy, Sensor

there are a number of methods that are commonly employed.

Figure 15-62 shows a basic paddle wheel flow meter. A pad-

dle wheel is placed in the flow of a liquid and allowed to Flow

rotate. The output of the paddle wheel drives a tachometer

generator that, in turn, outputs a proportional signal to a volt- Flow Cowling

meter. These types of flow meters are very inexpensive and Turbine Rotor

provide good performance. Because of the generator drive, Support Spiders

they do create a certain amount of backpressure and, there- Figure 15-64 Pulse Generating Turbine Flow Meter

fore, restrict the flow to a certain degree.

Connector

Generator Voltmeter

Signal Output

Drive Belt Sensor Housing

Paddle Wheel

Flow

Figure 15-62 Paddle Wheel Flow Meter

To limit the backpressure of a paddle wheel flow meter, the

generator can be replaced with a proximity sensor, as shown

Turbine Housing

in Figure 15-63. The sensor detects the passing paddle and

Standard Pipe Flanges

outputs a pulse each time. The sensor is interfaced to a con-

troller that drives a voltmeter calibrated in flow units. Another Figure 15-65 Commercial Turbine Flow Meter

attribute to flow meters with proximity sensors is that the

moving element is sealed within the housing and there are no

rotational seals to create leaks.

A variation of the paddle wheel flow meter is the turbine One of the most common methods for measuring flow is

unit. These transducers operate in the same manner as the through pressure drop. By measuring the pressure drop

through a restriction, the flow rate of a given fluid can be

determined with a high degree of accuracy.

Figure 15-66 shows a stylized sectional view of a differen-

Output

tial pressure flow meter. The fluid is forced to flow through a

restrictor orifice, which is bridged with two resistive pressure

Sensor

transducers. The pressure transducers make up two elements

of a Wheatstone bridge and the meter reads only the voltage

generated by differential resistance of the two transducers.

Paddle Wheel Figure 15-67 shows a typical commercial differential pres-

sure flow meter and readout. These units are often constructed

by sandwiching an orifice plate between two standard flanges,

Flow

as shown. To change the flow characteristics of the transducer,

Figure 15-63 Pulse Generating Paddle Wheel Flow Meter one only needs to swap out the orifice plate.