Page 59 - Electromechanical Devices and Components Illustrated Sourcebook

P. 59

Chapter 3 Power Sources 21

−

+ It should be noted that the higher the surface area of the

plates, the greater the battery’s current capacity will be.

Negative Positive terminal Surface area can be gained by using either larger plates or a

Terminal higher plate count. The proximity of the plates to one another

will also affect current capacity. The closer the plates are to

one another, the higher the battery’s current capacity will be.

Copper Plates Hard Rubber Figure 3-13 shows a few common automotive batteries.

Container Obviously, the larger the equipment, the greater the electrical

Zinc Plates

load and, therefore, the larger the battery. As an example,

motorcycles generally have very small batteries that can fit in

the palm of your hand. On the other hand, heavy construction

equipment may use batteries that weigh several hundred

pounds.

Plastic Bolt

Dilute Sulfuric Acid

(Electrolyte)

Figure 3-11 Bench Built Lead/Acid Storage Battery

Lawn Tractor

Battery

Economy Car

understanding of their interworkings. Figure 3-11 shows a Battery

sectional view of a bench built lead/acid storage battery. The

container should be a nonbreakable unit that is impervious to Motorcycle

sulfuric acid, such as hard rubber. The copper and zinc plates Battery

are alternated in an array and immersed into the acid solution.

The electrolyte is made by blending 18% sulfuric acid with

82% distilled water.

Truck Battery

Figure 3-12 shows an exploded view of the battery assem-

bly. The plastic-threaded rods at the bottom of the plates are

there to control spacing. The brass rods at the top of the plates

act as battery terminals as well as clamping bolts.

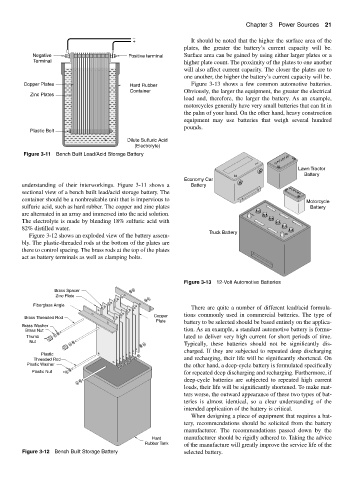

Figure 3-13 12-Volt Automotive Batteries

Brass Spacer

Zinc Plate

Fiberglass Angle

There are quite a number of different lead/acid formula-

Copper tions commonly used in commercial batteries. The type of

Brass Threaded Rod

Plate battery to be selected should be based entirely on the applica-

Brass Washer

Brass Nut tion. As an example, a standard automotive battery is formu-

Thumb lated to deliver very high current for short periods of time.

Nut

Typically, these batteries should not be significantly dis-

charged. If they are subjected to repeated deep discharging

Plastic

Threaded Rod and recharging, their life will be significantly shortened. On

Plastic Washer the other hand, a deep-cycle battery is formulated specifically

Plastic Nut for repeated deep discharging and recharging. Furthermore, if

deep-cycle batteries are subjected to repeated high current

loads, their life will be significantly shortened. To make mat-

ters worse, the outward appearance of these two types of bat-

teries is almost identical, so a clear understanding of the

intended application of the battery is critical.

When designing a piece of equipment that requires a bat-

tery, recommendations should be solicited from the battery

manufacturer. The recommendations passed down by the

Hard manufacturer should be rigidly adhered to. Taking the advice

Rubber Tank of the manufacture will greatly improve the service life of the

Figure 3-12 Bench Built Storage Battery selected battery.