Page 63 - Electromechanical Devices and Components Illustrated Sourcebook

P. 63

Chapter 3 Power Sources 25

used under the hood of a car or truck. They have two short

1100 cables with high current terminal clamps. The case of the

Discharged tester is ventilated to release the heat that is generated during

testing.

Specific 1200

Gravity Scale

Half Charged

Battery Charging

Fully Charged

1300

Standard dry cells are not rechargeable and must be discarded

after the charge is spent. However, there are a variety of

rechargeable batteries. To recharge a battery, a charger must

Glass

Ampoule be used. For lead/acid batteries the charger is little more than

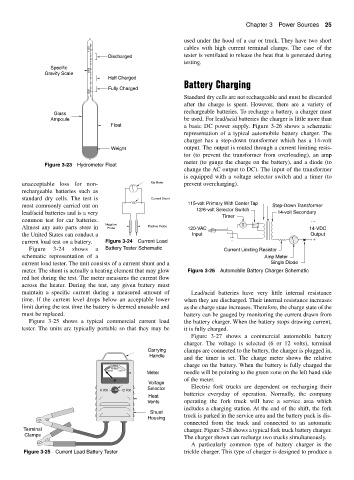

Float a basic DC power supply. Figure 3-26 shows a schematic

representation of a typical automobile battery charger. The

charger has a step-down transformer which has a 14-volt

Weight output. The output is routed through a current limiting resis-

tor (to prevent the transformer from overloading), an amp

meter (to gauge the charge on the battery), and a diode (to

Figure 3-23 Hydrometer Float

change the AC output to DC). The input of the transformer

is equipped with a voltage selector switch and a timer (to

unacceptable loss for non- Ma Meter prevent overcharging).

rechargeable batteries such as

standard dry cells. The test is Current Shunt

115-volt Primary With Center Tap

most commonly carried out on Step-Down Transformer

12/6-volt Selector Switch

lead/acid batteries and is a very 14-volt Secondary

Timer

common test for car batteries. −

Negative T

Almost any auto parts store in Probe Positive Probe 120-VAC 14-VDC

the United States can conduct a Input Output

current load test on a battery. Figure 3-24 Current Load +

Figure 3-24 shows a Battery Tester Schematic Current Limiting Resistor

schematic representation of a Amp Meter

current load tester. The unit consists of a current shunt and a Single Diode

meter. The shunt is actually a heating element that may glow Figure 3-26 Automobile Battery Charger Schematic

red hot during the test. The meter measures the current flow

across the heater. During the test, any given battery must

maintain a specific current during a measured amount of Lead/acid batteries have very little internal resistance

time. If the current level drops below an acceptable lower when they are discharged. Their internal resistance increases

limit during the test time the battery is deemed unusable and as the charge state increases. Therefore, the charge state of the

must be replaced. battery can be gauged by monitoring the current drawn from

Figure 3-25 shows a typical commercial current load the battery charger. When the battery stops drawing current,

tester. The units are typically portable so that they may be it is fully charged.

Figure 3-27 shows a commercial automobile battery

charger. The voltage is selected (6 or 12 volts), terminal

Carrying clamps are connected to the battery, the charger is plugged in,

Handle

and the timer is set. The charge meter shows the relative

charge on the battery. When the battery is fully charged the

Recharge

Replace Good

Meter needle will be pointing to the green zone on the left hand side

of the meter.

Voltage

Selector Electric fork trucks are dependent on recharging their

6 Volt 12 Volt

batteries everyday of operation. Normally, the company

Heat

Vents operating the fork truck will have a service area which

includes a charging station. At the end of the shift, the fork

Shunt

Housing truck is parked in the service area and the battery pack is dis-

connected from the truck and connected to an automatic

Terminal charger. Figure 3-28 shows a typical fork truck battery charger.

Clamps

The charger shown can recharge two trucks simultaneously.

A particularly common type of battery charger is the

Figure 3-25 Current Load Battery Tester trickle charger. This type of charger is designed to produce a