Page 67 - Academic Press Encyclopedia of Physical Science and Technology 3rd BioTechnology

P. 67

P1: GRB Final Pages

Encyclopedia of Physical Science and Technology EN002G-67 May 25, 2001 20:8

Bioreactors 249

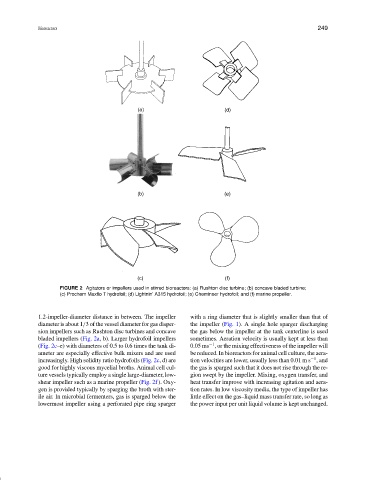

FIGURE 2 Agitators or impellers used in stirred bioreactors: (a) Rushton disc turbine; (b) concave bladed turbine;

(c) Prochem Maxflo T hydrofoil; (d) Lightnin’ A315 hydrofoil; (e) Chemineer hydrofoil; and (f) marine propeller.

1.2-impeller-diameter distance in between. The impeller with a ring diameter that is slightly smaller than that of

diameter is about 1/3 of the vessel diameter for gas disper- the impeller (Fig. 1). A single hole sparger discharging

sion impellers such as Rushton disc turbines and concave the gas below the impeller at the tank centerline is used

bladed impellers (Fig. 2a, b). Larger hydrofoil impellers sometimes. Aeration velocity is usually kept at less than

−1

(Fig. 2c–e) with diameters of 0.5 to 0.6 times the tank di- 0.05 ms , or the mixing effectiveness of the impeller will

ameter are especially effective bulk mixers and are used be reduced. In bioreactors for animal cell culture, the aera-

−1

increasingly. High solidity ratio hydrofoils (Fig. 2c, d) are tion velocities are lower, usually less than 0.01 m s , and

good for highly viscous mycelial broths. Animal cell cul- the gas is sparged such that it does not rise through the re-

ture vessels typically employ a single large-diameter, low- gion swept by the impeller. Mixing, oxygen transfer, and

shear impeller such as a marine propeller (Fig. 2f ). Oxy- heat transfer improve with increasing agitation and aera-

gen is provided typically by sparging the broth with ster- tion rates. In low viscosity media, the type of impeller has

ile air. In microbial fermenters, gas is sparged below the little effect on the gas–liquid mass transfer rate, so long as

lowermost impeller using a perforated pipe ring sparger the power input per unit liquid volume is kept unchanged.