Page 71 - Academic Press Encyclopedia of Physical Science and Technology 3rd BioTechnology

P. 71

P1: GRB Final Pages

Encyclopedia of Physical Science and Technology EN002G-67 May 25, 2001 20:8

Bioreactors 253

lized enzyme reactors and “biofilters” for the treatment of

gaseous pollutants. Such reactors are particularly attrac-

tive for product inhibited reactions: the product concen-

tration varies from a low value at the inlet of the bed to

a high value at the exit; thus, only a part of the biocat-

alyst is exposed to high inhibitory levels of the product.

In contrast, if the catalyst particles were suspended in a

well mixed stirred vessel, all the catalyst will experience

the same inhibitory product concentration as in the fluid

stream that leaves the reactor.

6. Photobioreactors

Photobioreactors are used for photosynthetic culture of

cyanobacteria, microalgae, and to a much lesser extent,

cells of macroalgae (seaweeds) and plants. Photosynthe-

sis requires light and light stimulates some cultures in

ways not seen in purely heterotrophic growth. Because of

the need to provide light, photobioreactors must have a

high surface-to-volume ratio and this greatly affects the

design of bioreactor. The demand for light is reduced in

photomixotrophic culture where an organic compound is

the major source of carbon for the cells and only a lim-

ited amount of photosynthesis (i.e., the fixation of carbon

dioxide in presence of light) takes place.

Onlyafewphototrophicmicroorganismsmainlycyano-

bacteria and microalgae are cultured on large scale. This

kind of mass culture is carried out in photobioreactors

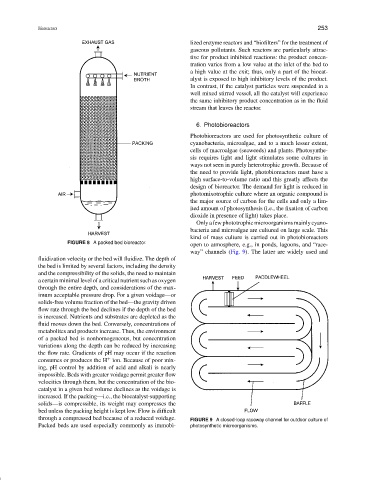

FIGURE 8 A packed bed bioreactor. open to atmosphere, e.g., in ponds, lagoons, and “race-

way” channels (Fig. 9). The latter are widely used and

fluidization velocity or the bed will fluidize. The depth of

the bed is limited by several factors, including the density

and the compressibility of the solids, the need to maintain

a certain minimal level of a critical nutrient such as oxygen

through the entire depth, and considerations of the max-

imum acceptable pressure drop. For a given voidage—or

solids-free volume fraction of the bed—the gravity driven

flow rate through the bed declines if the depth of the bed

is increased. Nutrients and substrates are depleted as the

fluid moves down the bed. Conversely, concentrations of

metabolites and products increase. Thus, the environment

of a packed bed is nonhomogeneous, but concentration

variations along the depth can be reduced by increasing

the flow rate. Gradients of pH may occur if the reaction

consumes or produces the H ion. Because of poor mix-

+

ing, pH control by addition of acid and alkali is nearly

impossible. Beds with greater voidage permit greater flow

velocities through them, but the concentration of the bio-

catalyst in a given bed volume declines as the voidage is

increased. If the packing—i.e., the biocatalyst-supporting

solids—is compressible, its weight may compresses the

bed unless the packing height is kept low. Flow is difficult

through a compressed bed because of a reduced voidage. FIGURE 9 A closed-loop raceway channel for outdoor culture of

Packed beds are used especially commonly as immobi- photosynthetic microorganisms.