Page 74 - Academic Press Encyclopedia of Physical Science and Technology 3rd BioTechnology

P. 74

P1: GRB Final Pages

Encyclopedia of Physical Science and Technology EN002G-67 May 25, 2001 20:8

256 Bioreactors

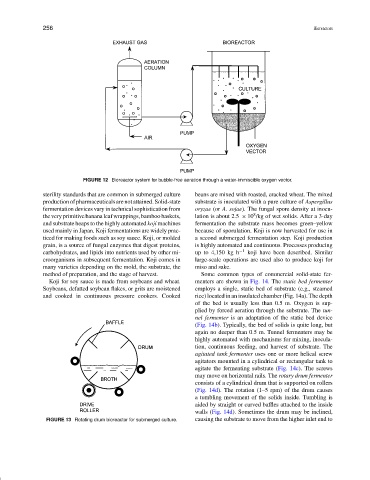

FIGURE 12 Bioreactor system for bubble-free aeration through a water-immiscible oxygen vector.

sterility standards that are common in submerged culture beans are mixed with roasted, cracked wheat. The mixed

production of pharmaceuticals are not attained. Solid-state substrate is inoculated with a pure culture of Aspergillus

fermentation devices vary in technical sophistication from oryzae (or A. sojae). The fungal spore density at inocu-

8

theveryprimitivebananaleafwrappings,bamboobaskets, lation is about 2.5 × 10 /kg of wet solids. After a 3-day

and substrate heaps to the highly automated koji machines fermentation the substrate mass becomes green–yellow

used mainly in Japan. Koji fermentations are widely prac- because of sporulation. Koji is now harvested for use in

ticed for making foods such as soy sauce. Koji, or molded a second submerged fermentation step. Koji production

grain, is a source of fungal enzymes that digest proteins, is highly automated and continuous. Processes producing

carbohydrates, and lipids into nutrients used by other mi- up to 4,150 kg h −1 koji have been described. Similar

croorganisms in subsequent fermentation. Koji comes in large-scale operations are used also to produce koji for

many varieties depending on the mold, the substrate, the miso and sake.

method of preparation, and the stage of harvest. Some common types of commercial solid-state fer-

Koji for soy sauce is made from soybeans and wheat. menters are shown in Fig. 14. The static bed fermenter

Soybeans, defatted soybean flakes, or grits are moistened employs a single, static bed of substrate (e.g., steamed

and cooked in continuous pressure cookers. Cooked rice) located in an insulated chamber (Fig. 14a). The depth

of the bed is usually less than 0.5 m. Oxygen is sup-

plied by forced aeration through the substrate. The tun-

nel fermenter is an adaptation of the static bed device

(Fig. 14b). Typically, the bed of solids is quite long, but

again no deeper than 0.5 m. Tunnel fermenters may be

highly automated with mechanisms for mixing, inocula-

tion, continuous feeding, and harvest of substrate. The

agitated tank fermenter uses one or more helical screw

agitators mounted in a cylindrical or rectangular tank to

agitate the fermenting substrate (Fig. 14c). The screws

may move on horizontal rails. The rotary drum fermenter

consists of a cylindrical drum that is supported on rollers

(Fig. 14d). The rotation (1–5 rpm) of the drum causes

a tumbling movement of the solids inside. Tumbling is

aided by straight or curved baffles attached to the inside

walls (Fig. 14d). Sometimes the drum may be inclined,

FIGURE 13 Rotating drum bioreactor for submerged culture. causing the substrate to move from the higher inlet end to