Page 70 - Academic Press Encyclopedia of Physical Science and Technology 3rd BioTechnology

P. 70

P1: GRB Final Pages

Encyclopedia of Physical Science and Technology EN002G-67 May 25, 2001 20:8

252 Bioreactors

cial liquid velocity needed to suspend the solids may be

so high that the liquid leaves the reactor much too quickly,

i.e., the solid–liquid contact time may be insufficient for

the reaction and the liquid may have to be recycled to ob-

tain a sufficiently long cumulative contact time with the

biocatalyst. The minimum fluidization velocity—i.e., the

superficial liquid velocity needed to just suspend the solids

from a settled state—depends on several factors, including

the density difference between the phases, the shape and

diameter of the particles, and the viscosity of the liquid.

5. Packed Bed Bioreactors

A bed of solid particles usually with confining walls

(Fig. 8) constitutes a packed bed. The biocatalyst is sup-

ported on or within the solid matrix that may be porous or

FIGURE 6 Gas–liquid separators for airlift bioreactors: (a) ex- a homogeneous non-porous gel. The solids may be ridged,

tended length of the flow path in the head zone, (b) enlarged or only slightly compressible. The particles may be ran-

entrance cross section of the downcomer zone.

domly shaped (e.g., wood chips and rocks) or they may be

uniform spheres, cylinders, cubes, or some other shape. A

to a reactor without a gas–liquid separator, installation of fluid containing dissolved nutrients and substrates flows

a suitably designed separator will always enhance liquid through the solid bed to provide the needs of the immo-

circulation, i.e., the increased driving force for circulation bilized biocatalyst. Metabolites and products are released

will more than compensate for any additional resistance into the fluid and are taken out with the flow. The flow

to flow due to the separator. may be upward or downward, but downflow under grav-

ity (i.e., trickle bed operation) is the norm specially if

the immobilized biocatalyst requires oxygen (Fig. 8). If

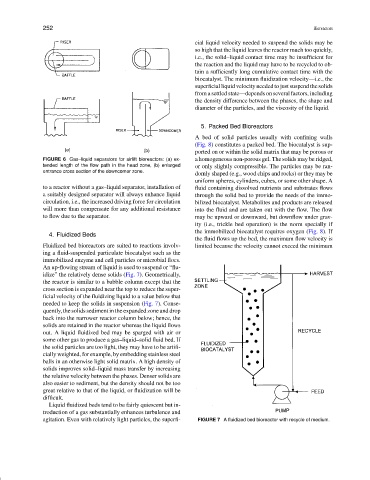

4. Fluidized Beds

the fluid flows up the bed, the maximum flow velocity is

Fluidized bed bioreactors are suited to reactions involv- limited because the velocity cannot exceed the minimum

ing a fluid-suspended particulate biocatalyst such as the

immobilized enzyme and cell particles or microbial flocs.

An up-flowing stream of liquid is used to suspend or “flu-

idize” the relatively dense solids (Fig. 7). Geometrically,

the reactor is similar to a bubble column except that the

cross section is expanded near the top to reduce the super-

ficial velocity of the fluidizing liquid to a value below that

needed to keep the solids in suspension (Fig. 7). Conse-

quently, the solids sediment in the expanded zone and drop

back into the narrower reactor column below; hence, the

solids are retained in the reactor whereas the liquid flows

out. A liquid fluidized bed may be sparged with air or

some other gas to produce a gas–liquid–solid fluid bed. If

the solid particles are too light, they may have to be artifi-

cially weighted, for example, by embedding stainless steel

balls in an otherwise light solid matrix. A high density of

solids improves solid–liquid mass transfer by increasing

the relative velocity between the phases. Denser solids are

also easier to sediment, but the density should not be too

great relative to that of the liquid, or fluidization will be

difficult.

Liquid fluidized beds tend to be fairly quiescent but in-

troduction of a gas substantially enhances turbulence and

agitation. Even with relatively light particles, the superfi- FIGURE 7 A fluidized bed bioreactor with recycle of medium.