Page 72 - Academic Press Encyclopedia of Physical Science and Technology 3rd BioTechnology

P. 72

P1: GRB Final Pages

Encyclopedia of Physical Science and Technology EN002G-67 May 25, 2001 20:8

254 Bioreactors

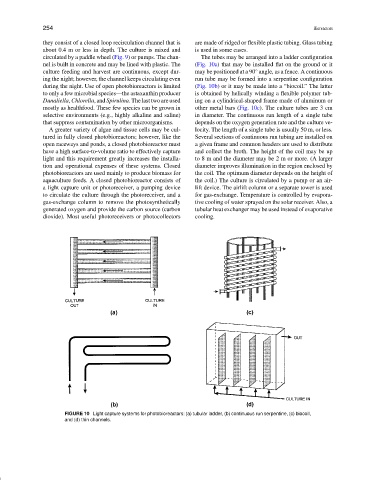

they consist of a closed loop recirculation channel that is are made of ridged or flexible plastic tubing. Glass tubing

about 0.4 m or less in depth. The culture is mixed and is used in some cases.

circulated by a paddle wheel (Fig. 9) or pumps. The chan- The tubes may be arranged into a ladder configuration

nel is built in concrete and may be lined with plastic. The (Fig. 10a) that may be installed flat on the ground or it

◦

culture feeding and harvest are continuous, except dur- may be positioned at a 90 angle, as a fence. A continuous

ing the night; however, the channel keeps circulating even run tube may be formed into a serpentine configuration

during the night. Use of open photobioreactors is limited (Fig. 10b) or it may be made into a “biocoil.” The latter

to only a few microbial species—the astaxanthin producer is obtained by helically winding a flexible polymer tub-

Dunaliella, Chlorella, and Spirulina. The last two are used ing on a cylindrical-shaped frame made of aluminum or

mostly as healthfood. These few species can be grown in other metal bars (Fig. 10c). The culture tubes are 3 cm

selective environments (e.g., highly alkaline and saline) in diameter. The continuous run length of a single tube

that suppress contamination by other microorganisms. depends on the oxygen generation rate and the culture ve-

A greater variety of algae and tissue cells may be cul- locity. The length of a single tube is usually 50 m, or less.

tured in fully closed photobioreactors; however, like the Several sections of continuous run tubing are installed on

open raceways and ponds, a closed photobioreactor must a given frame and common headers are used to distribute

have a high surface-to-volume ratio to effectively capture and collect the broth. The height of the coil may be up

light and this requirement greatly increases the installa- to 8 m and the diameter may be 2 m or more. (A larger

tion and operational expenses of these systems. Closed diameter improves illumination in the region enclosed by

photobioreactors are used mainly to produce biomass for the coil. The optimum diameter depends on the height of

aquaculture feeds. A closed photobioreactor consists of the coil.) The culture is circulated by a pump or an air-

a light capture unit or photoreceiver, a pumping device lift device. The airlift column or a separate tower is used

to circulate the culture through the photoreceiver, and a for gas-exchange. Temperature is controlled by evapora-

gas-exchange column to remove the photosynthetically tive cooling of water sprayed on the solar receiver. Also, a

generated oxygen and provide the carbon source (carbon tubular heat exchanger may be used instead of evaporative

dioxide). Most useful photoreceivers or photocollectors cooling.

FIGURE 10 Light capture systems for photobioreactors: (a) tubular ladder, (b) continuous run serpentine, (c) biocoil,

and (d) thin channels.