Page 176 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 176

P1: GGY Final Pages

Encyclopedia of Physical Science and Technology EN004D-156 June 8, 2001 15:28

Cryogenic Process Engineering 19

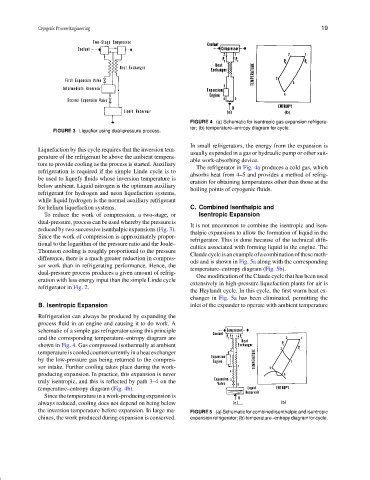

FIGURE 4 (a) Schematic for isentropic gas expansion refrigera-

tor; (b) temperature–entropy diagram for cycle.

FIGURE 3 Liquefier using dual-pressure process.

In small refrigerators, the energy from the expansion is

Liquefaction by this cycle requires that the inversion tem-

usually expended in a gas or hydraulic pump or other suit-

perature of the refrigerant be above the ambient tempera-

able work-absorbing device.

ture to provide cooling as the process is started. Auxiliary

The refrigerator in Fig. 4a produces a cold gas, which

refrigeration is required if the simple Linde cycle is to

absorbs heat from 4–5 and provides a method of refrig-

be used to liquefy fluids whose inversion temperature is

eration for obtaining temperatures other than those at the

below ambient. Liquid nitrogen is the optimum auxiliary

boiling points of cryogenic fluids.

refrigerant for hydrogen and neon liquefaction systems,

while liquid hydrogen is the normal auxiliary refrigerant

for helium liquefaction systems. C. Combined Isenthalpic and

To reduce the work of compression, a two-stage, or Isentropic Expansion

dual-pressure, process can be used whereby the pressure is

It is not uncommon to combine the isentropic and isen-

reduced by two successive isenthalpic expansions (Fig. 3).

thalpic expansions to allow the formation of liquid in the

Since the work of compression is approximately propor-

refrigerator. This is done because of the technical diffi-

tional to the logarithm of the pressure ratio and the Joule–

culties associated with forming liquid in the engine. The

Thomson cooling is roughly proportional to the pressure

Claudecycleisanexampleofacombinationofthesemeth-

difference, there is a much greater reduction in compres-

ods and is shown in Fig. 5a along with the corresponding

sor work than in refrigerating performance. Hence, the

temperature–entropy diagram (Fig. 5b).

dual-pressure process produces a given amount of refrig-

One modification of the Claude cycle that has been used

eration with less energy input than the simple Linde cycle

extensively in high-pressure liquefaction plants for air is

refrigerator in Fig. 2.

the Heylandt cycle. In this cycle, the first warm heat ex-

changer in Fig. 5a has been eliminated, permitting the

B. Isentropic Expansion inlet of the expander to operate with ambient temperature

Refrigeration can always be produced by expanding the

process fluid in an engine and causing it to do work. A

schematic of a simple gas refrigerator using this principle

and the corresponding temperature–entropy diagram are

shown in Fig. 4. Gas compressed isothermally at ambient

temperature is cooled countercurrently in a heat exchanger

by the low-pressure gas being returned to the compres-

sor intake. Further cooling takes place during the work-

producing expansion. In practice, this expansion is never

truly isentropic, and this is reflected by path 3–4onthe

temperature–entropy diagram (Fig. 4b).

Since the temperature in a work-producing expansion is

always reduced, cooling does not depend on being below

the inversion temperature before expansion. In large ma- FIGURE 5 (a) Schematic for combined isenthalpic and isentropic

chines, the work produced during expansion is conserved. expansion refrigerator; (b) temperature–entropy diagram for cycle.