Page 40 - Subyek Encyclopedia - Encyclopedia of Separation Science

P. 40

Sepsci*11*TSK*Venkatachala=BG

I / CENTRIFUGATION 35

tions for continuous-discharge disc centrifuges include

production of baker’s yeast, dewatering of kaolin

clay, titanium dioxide classiRcation, and coal-tar

and tar-sand clariRcation.

Continuous conveyor discharge These centrifuge

types integrate an active mechanical solids discharge

mechanism in an imperforate bowl for the continuous

processing of larger sample volumes. The bowl shape

is tubular, having a length-to-diameter ratio of

1.5}5.2, and may operate in either a horizontal or

vertical conRguration. The vertical conRguration is

generally preferred for reduced or elevated temper-

ature and/or pressure applications owing to fewer

mechanical problems with seals and heat expansion.

The solids-discharge mechanism is most commonly,

a helical screw turning at a slightly slower rate than

the rotor, though pistons or conveyer belts are also

used. Figure 13 illustrates a helical-screw conRg-

uration used for three-phase separations (liquid}

liquid}solid). Solid}liquid and liquid}liquid conRg-

urations with either concurrent or countercurrent

Sow regimes are commercially available. Such mech-

anical discharge units typically operate at lower cen-

trifugal forces (to 5000g) than disc centrifuges. How-

ever, they are capable of very high throughput, up to

1

300 000 L h , and can be used to process feed

streams containing up to 50% solids by volume.

While a limited number of industrial units operate on

materials smaller than 1 m, particles smaller than

about 2 m are usually not collected in such units,

a characteristic that is used to advantage for particle

classiRcation. Continuous conveyer centrifuges are

widely used in the chemical, mining, pharmaceutical,

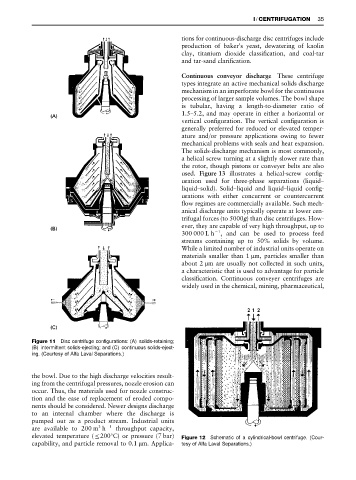

Figure 11 Disc centrifuge configurations: (A) solids-retaining;

(B) intermittent solids-ejecting; and (C) continuous solids-eject-

ing. (Courtesy of Alfa Laval Separations.)

the bowl. Due to the high discharge velocities result-

ing from the centrifugal pressures, nozzle erosion can

occur. Thus, the materials used for nozzle construc-

tion and the ease of replacement of eroded compo-

nents should be considered. Newer designs discharge

to an internal chamber where the discharge is

pumped out as a product stream. Industrial units

1

3

are available to 200 m h throughput capacity,

elevated temperature (42003C) or pressure (7 bar) Figure 12 Schematic of a cylindrical-bowl centrifuge. (Cour-

capability, and particle removal to 0.1 m. Applica- tesy of Alfa Laval Separations.)