Page 347 - Engineering Plastics Handbook

P. 347

304 Engineering Plastics

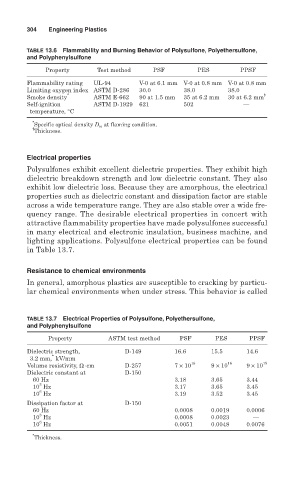

TABLE 13.6 Flammability and Burning Behavior of Polysulfone, Polyethersulfone,

and Polyphenylsulfone

Property Test method PSF PES PPSF

Flammability rating UL-94 V-0 at 6.1 mm V-0 at 0.8 mm V-0 at 0.8 mm

Limiting oxygen index ASTM D-286 30.0 38.0 38.0

Smoke density * ASTM E-662 90 at 1.5 mm 35 at 6.2 mm 30 at 6.2 mm †

Self-ignition ASTM D-1929 621 502 —

temperature, °C

*

Specific optical density D m at flaming condition.

†

Thickness.

Electrical properties

Polysulfones exhibit excellent dielectric properties. They exhibit high

dielectric breakdown strength and low dielectric constant. They also

exhibit low dielectric loss. Because they are amorphous, the electrical

properties such as dielectric constant and dissipation factor are stable

across a wide temperature range. They are also stable over a wide fre-

quency range. The desirable electrical properties in concert with

attractive flammability properties have made polysulfones successful

in many electrical and electronic insulation, business machine, and

lighting applications. Polysulfone electrical properties can be found

in Table 13.7.

Resistance to chemical environments

In general, amorphous plastics are susceptible to cracking by particu-

lar chemical environments when under stress. This behavior is called

TABLE 13.7 Electrical Properties of Polysulfone, Polyethersulfone,

and Polyphenylsulfone

Property ASTM test method PSF PES PPSF

Dielectric strength, D-149 16.6 15.5 14.6

*

3.2 mm, kV/mm

Volume resistivity, Ω⋅cm D-257 7 × 10 16 9 × 10 16 9 × 10 15

Dielectric constant at D-150

60 Hz 3.18 3.65 3.44

3

10 Hz 3.17 3.65 3.45

6

10 Hz 3.19 3.52 3.45

Dissipation factor at D-150

60 Hz 0.0008 0.0019 0.0006

3

10 Hz 0.0008 0.0023 —

6

10 Hz 0.0051 0.0048 0.0076

*

Thickness.