Page 182 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 182

Fundamentals of Assembly Modeling Engineering Design with SOLIDWORKS® 2018

Project Situation

The PLATE, ROD and GUIDE parts were created in Project 2. Perform the following

steps:

Step 1: Insert the ROD, GUIDE and PLATE into a GUIDE-ROD assembly.

Step 2: Obtain the customer's GUIDE-CYLINDER assembly using 3D ContentCentral.

The assembly is obtained to guarantee proper fit between the GUIDE-ROD assembly and

the customer's GUIDE-CYLINDER assembly.

Step 3: Create the CUSTOMER assembly. The CUSTOMER assembly combines the

GUIDE-ROD assembly with the GUIDE-CYLINDER assembly.

Review the GUIDE-ROD assembly design constraints:

• The ROD requires the ability to travel through the GUIDE.

• The ROD keyway is parallel to the right surface of the GUIDE. The top surface of the

GUIDE is parallel to the work area.

• The ROD mounts to the PLATE. The GUIDE mounts to a flat work surface.

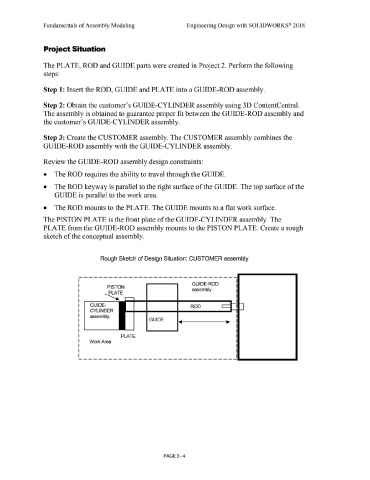

The PISTON PLATE is the front plate of the GUIDE-CYLINDER assembly. The

PLATE from the GUIDE-ROD assembly mounts to the PISTON PLATE. Create a rough

sketch of the conceptual assembly.

Rough Sketch of Design Situation: CUSTOMER assembly

--------------------------------

GUIDE-ROD

PISTON

assembly

~E .....-----,

....... __ ...... ______ ...... __________ ...

GUIDE- ROD

CYLINDER

assembly

GUIDE

PLATE

Work Area

---------------------------------------------

PAGE 3-4