Page 184 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 184

Fundamentals of Assembly Modeling Engineering Design with SOLIDWORKS® 2018

In the Top-down assembly approach, major

l:rn fo ~ I

design requirements are translated into \7-

assemblies, sub-assemblies and components. L, Origin

• IC@ (f) Side< 1 > (Standard < <Standard> _I

• ~ Side<2> (Standard< <Standard> _Dis

, 1 / • ~ Ball<1 > (Standard<<Standard> _Pho

• ~ Handle<1> (Standard<<Standard>_I

-;Q~ In the Top-down approach, you do not (!, I Part1 lnplace Mate 11-1 ]<1> -> (

11

need all of the required component design • fil Mates in lnplace Mate 11-1

• ~] History

details. Individual relationships are required. ~ Sensors

• IA] Annotations

rfl Equations

.,_

Example: A computer. The inside of a ~~ Material <not specified>

C!J Front Plane

computer can be divided into individual key

C!J Top Plane

sub-assemblies such as a motherboard, disk drive, power [iJ Right Plane

L Origin

supply, etc. Relationships between these sub-assemblies • ~ Boss-Extrudel ->

must be maintained for proper fit. • ~ ( Part2"1nplace Mate 11-1 )<1> ·> (

Use the Bottom-up design approach for the GUIDE-ROD

assembly and the CUSTOMER assembly.

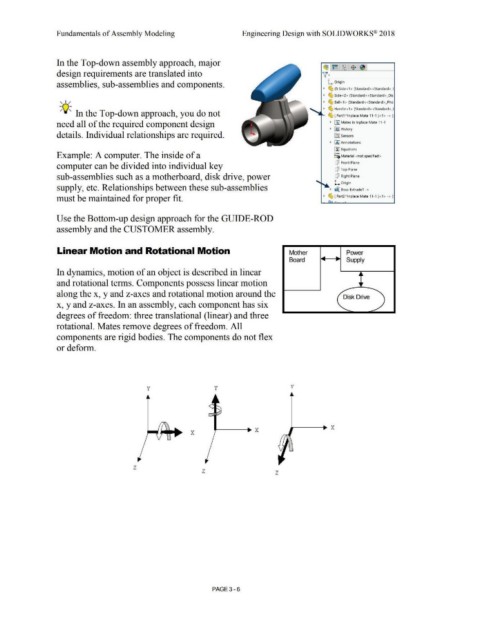

Linear Motion and Rotational Motion Mother Power

Board Supply

In dynamics, motion of an object is described in linear

and rotational terms. Components possess linear motion

along the x, y and z-axes and rotational motion around the Disk Drive

x, y and z-axes. In an assembly, each component has six

degrees of freedom: three translational (linear) and three

rotational. Mates remove degrees of freedom. All

components are rigid bodies. The components do not flex

or deform.

y y v

x

z

z z

PAGE 3- 6