Page 477 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 477

Engineering Design with SOLIDWORKS® 2018 Swept, Lofted and Additional Features

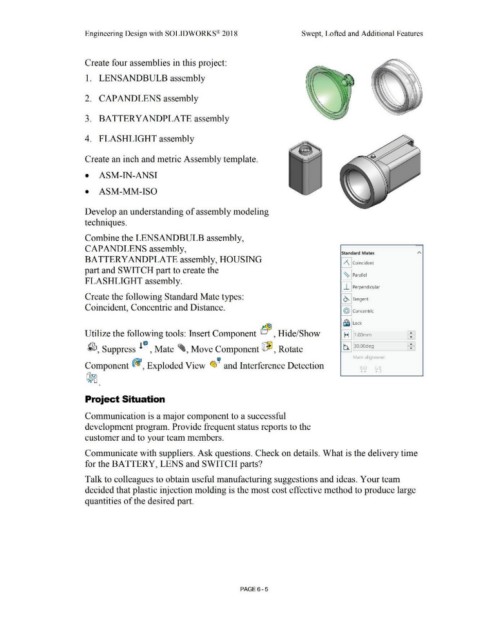

Create four assemblies in this project:

1. LENSANDBULB assembly

2. CAP ANDLENS assembly

3. BATTERYANDPLATE assembly

4. FLASHLIGHT assembly

Create an inch and metric Assembly template.

• ASM-IN-ANSI

• ASM-MM-ISO

Develop an understanding of assembly modeling

techniques.

Combine the LENSANDBULB assembly,

CAP AND LENS assembly,

Standard Mates

BATTERYANDPLATE assembly, HOUSING

I /\ I Coincident

part and SWITCH part to create the

I ~ I Parallel

FLASHLIGHT assembly.

I ..i I Perpendicular

Create the following Standard Mate types:

I°' !Tangent

Coincident, Concentric and Distance.

I @ I Concentric

l~llock

Utilize the following tools: Insert Component ~ , Hide/Show [8J .--[, .o-om-m-------,.! ....... : ]

O I : ]

~, Suppress l , Mate ~, Move Component CTjl, Rotate I b. I [30.00deg

I@ ~ Mate alignment:

Component "'-~ , Exploded View ~ ·-· and Interference Detection

~

•

Project Situation

Communication is a major component to a successful

development program. Provide frequent status reports to the

customer and to your team members.

Communicate with suppliers. Ask questions. Check on details. What is the delivery time

for the BATTERY, LENS and SWITCH parts?

Talk to colleagues to obtain useful manufacturing suggestions and ideas. Your team

decided that plastic injection molding is the most cost effective method to produce large

quantities of the desired part.

PAGE 6 - 5