Page 105 - Failure Analysis Case Studies II

P. 105

90

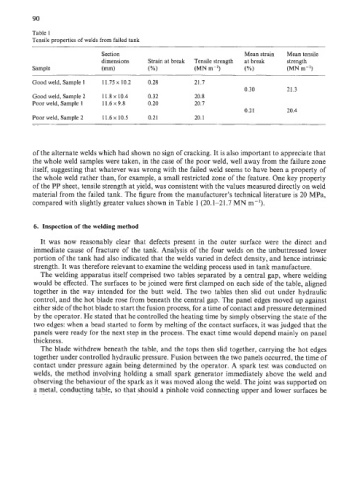

Table 1

Tensile properties of welds from failed tank

Section Mean strain Mean tensile

dimensions Strain at break Tensile strength at break strength

Sample (mm) (%I (MN m-*) (%) (MN m-*)

Good weld, Sample 1 11.75 x 10.2 0.28 21.7

0.30 21.3

Good weld, Sample 2 1 1.8 x 10.4 0.32 20.8

Poor weld, Sample 1 11.6x9.8 0.20 20.7

0.21 20.4

Poor weld, Sample 2 11.6~ 10.5 0.21 20.1

of the alternate welds which had shown no sign of cracking. It is also important to appreciate that

the whole weld samples were taken, in the case of the poor weld, well away from the failure zone

itself, suggesting that whatever was wrong with the failed weld seems to have been a property of

the whole weld rather than, for example, a small restricted zone of the feature. One key property

of the PP sheet, tensile strength at yield, was consistent with the values measured directly on weld

material from the failed tank. The figure from the manufacturer’s technical literature is 20 MPa,

compared with slightly greater values shown in Table 1 (20.1-2 1.7 MN m-’).

6. Inspection of the welding method

It was now reasonably clear that defects present in the outer surface were the direct and

immediate cause of fracture of the tank. Analysis of the four welds on the unbuttressed lower

portion of the tank had also indicated that the welds varied in defect density, and hence intrinsic

strength. It was therefore relevant to examine the welding process used in tank manufacture.

The welding apparatus itself comprised two tables separated by a central gap, where welding

would be effected. The surfaces to be joined were first clamped on each side of the table, aligned

together in the way intended for the butt weld. The two tables then slid out under hydraulic

control, and the hot blade rose from beneath the central gap. The panel edges moved up against

either side of the hot blade to start the fusion process, for a time of contact and pressure determined

by the operator. He stated that he controlled the heating time by simply observing the state of the

two edges: when a bead started to form by melting of the contact surfaces, it was judged that the

panels were ready for the next step in the process. The exact time would depend mainly on panel

thickness.

The blade withdrew beneath the table, and the tops then slid together, carrying the hot edges

together under controlled hydraulic pressure. Fusion between the two panels occurred, the time of

contact under pressure again being determined by the operator. A spark test was conducted on

welds, the method involving holding a small spark generator immediately above the weld and

observing the behaviour of the spark as it was moved along the weld. The joint was supported on

a metal, conducting table, so that should a pinhole void connecting upper and lower surfaces be