Page 19 - Failure Analysis Case Studies II

P. 19

6

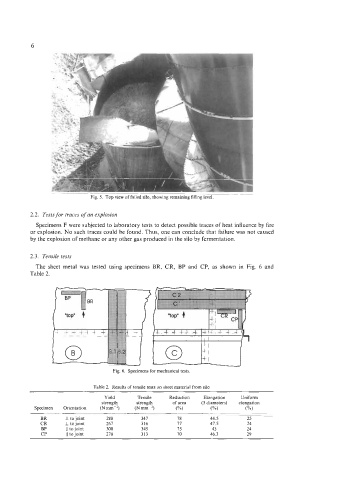

Fig. 5. Top view of failed silo, showing remaining filling level.

2.2. Tests for traces of an explosion

Specimens F were subjected to laboratory tests to detect possible traces of heat influence by fire

or explosion. No such traces could be found. Thus, one can conclude that failure was not caused

by the explosion of methane or any other gas produced in the silo by fermentation.

2.3. Tensile tests

The sheet metal was tested using specimens BR, CR, BP and CP, as shown in Fig. 6 and

Table 2.

Fig 6. Specimens for mechanical tests.

Table 2. Results of tensile tests on sheet material from silo

Yield Tensile Reduction Elongation Uniform

strength strength of area (5 diameters) elongation

Specimen Orientation (N~II-~) (N~II-~) (”/) (”/I (”/)

BR I to joint 288 341 18 44.5 25

CR I to joint 261 316 I1 47.5 24

BP 11 to joint 300 345 IS 43 24

CP 1) to joint 278 313 70 46.3 29