Page 241 - Failure Analysis Case Studies II

P. 241

226

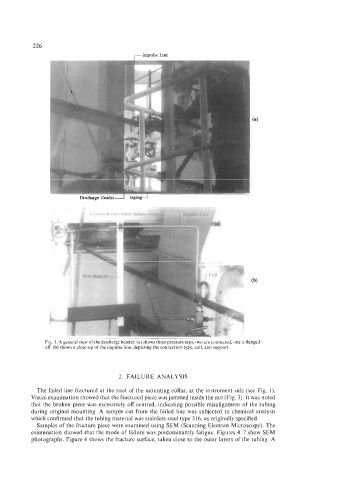

,- Impulsc Linc

Fig. 1. A general view of the discharge header: (a) shows three pressure taps, two are connected, one is flanged-

off. (b) shows a close-up of the impulse line, depicting the connection-type, coil, and support.

2. FAILURE ANALYSIS

The failed line fractured at the root of the mounting collar, at the instrument side (see Fig. 1).

Visual examination showed that the fractured piece was jammed inside the nut (Fig. 3). It was noted

that the broken piece was excessively off centred, indicating possible misalignment of the tubing

during original mounting. A sample cut from the failed line was subjected to chemical analysis

which confirmed that the tubing material was stainless steel type 3 16, as originally specified.

Samples of the fracture piece were examined using SEM (Scanning Electron Microscopy). The

examination showed that the mode of failure was predominantly fatigue. Figures 4-7 show SEM

photographs. Figure 4 shows the fracture surface, taken close to the outer layers of the tubing. A