Page 308 - Failure Analysis Case Studies II

P. 308

293

I .25

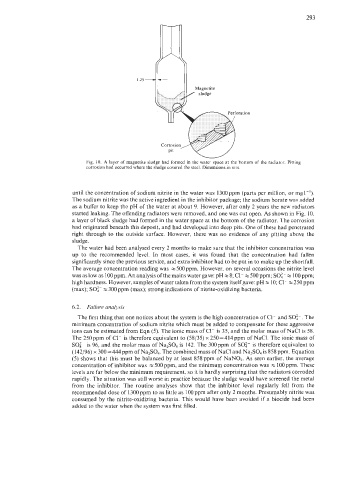

Fig. 10. A layer of magnetite sludge had formed in the water space at the bottom of the radiator. Pitting

corrosion had occurred where the sludge covered the steel. Dimensions in mm.

until the concentration of sodium nitrite in the water was 1300ppm (parts per million, or mgl-’).

The sodium nitrite was the active ingredient in the inhibitor package; the sodium borate was added

as a buffer to keep the pH of the water at about 9. However, after only 2 years the new radiators

started leaking. The offending radiators were removed, and one was cut open. As shown in Fig. 10,

a layer of black sludge had formed in the water space at the bottom of the radiator. The corrosion

had originated beneath this deposit, and had developed into deep pits. One of these had penetrated

right through to the outside surface. However, there was no evidence of any pitting above the

sludge.

The water had been analysed every 2 months to make sure that the inhibitor concentration was

up to the recommended level. In most cases, it was found that the Concentration had fallen

significantly since the previous service, and extra inhibitor had to be put in to make up the shortfall.

The average concentration reading was E 500 ppm. However, on several occasions the nitrite level

was as low as 100 ppm. An analysis of the mains water gave: pH E 8; C1- z 500 ppm; SO:- E 100 ppm;

high hardness. However, samples of water taken from the system itself gave: pH z 10; C1- z 250 ppm

(max); SO:- z 300 ppm (max); strong indications of nitrite-oxidizing bacteria.

6.2. Failure analysis

The first thing that one notices about the system is the high concentration of C1- and SO:-, The

minimum concentration of sodium nitrite which must be added to compensate for these aggressive

ions can be estimated from Eqn (5). The ionic mass of CI- is 35, and the molar mass of NaCl is 58.

The 250ppm of C1- is therefore equivalent to (58/35) x 250=414ppm of NaC1. The ionic mass of

SO:- is 96, and the molar mass of Na2S0, is 142. The 300ppm of SO:- is therefore equivalent to

(142/96) x 300 = 444 ppm of Na,SO,. The combined mass of NaCl and Na2S0, is 858 ppm. Equation

(5) shows that this must be balanced by at least 858ppm of NaNO,. As seen earlier, the average

concentration of inhibitor was E 500ppm, and the minimum concentration was E 100ppm. These

levels are far below the minimum requirement, so it is hardly surprising that the radiators corroded

rapidly. The situation was still worse in practice because the sludge would have screened the metal

from the inhibitor. The routine analyses show that the inhibitor level regularly fell from the

recommended dose of 1300ppm to as little as l0Oppm after only 2 months. Presumably nitrite was

consumed by the nitrite-oxidizing bacteria. This would have been avoided if a biocide had been

added to the water when the system was first filled.