Page 312 - Failure Analysis Case Studies II

P. 312

297

Pipe Polystyrene

Screed

1 Floor oanel 1

4

I

t-330---

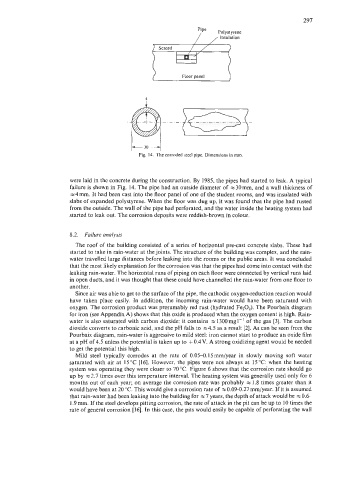

Fig. 14. The corroded steel pipe. Dimensions in mm.

were laid in the concrete during the construction. By 1985, the pipes had started to leak. A typical

failure is shown in Fig. 14. The pipe had an outside diameter of x 30 mm, and a wall thickness of

x4mm. It had been cast into the floor panel of one of the student rooms, and was insulated with

slabs of expanded polystyrene. When the floor was dug up, it was found that the pipe had rusted

from the outside. The wall of the pipe had perforated, and the water inside the heating system had

started to leak out. The corrosion deposits were reddish-brown in colour.

8.2. Failure analysis

The roof of the building consisted of a series of horizontal pre-cast concrete slabs. These had

started to take in rain-water at the joints. The structure of the building was complex, and the rain-

water travelled large distances before leaking into the rooms or the public areas. It was concluded

that the most likely explanation for the corrosion was that the pipes had come into contact with the

leaking rain-water. The horizontal runs of piping on each floor were connected by vertical runs laid

in open ducts, and it was thought that these could have channelled the rain-water from one floor to

another.

Since air was able to get to the surface of the pipe, the cathodic oxygen-reduction reaction would

have taken place easily. In addition, the incoming rain-water would have been saturated with

oxygen. The corrosion product was presumably red rust (hydrated Fe,03). The Pourbaix diagram

for iron (see Appendix A) shows that this oxide is produced when the oxygen content is high. Rain-

water is also saturated with carbon dioxide: it contains % 1300mgI-' of the gas [3]. The carbon

dioxide converts to carbonic acid, and the pH falls to =4.5 as a result [2]. As can be seen from the

Pourbaix diagram, rain-water is aggressive to mild steel: iron cannot start to produce an oxide film

at a pH of 4.5 unless the potential is taken up to +0.4V. A strong oxidizing agent would be needed

to get the potential this high.

Mild steel typically corrodes at the rate of 0.05-0.15mm/year in slowly moving soft water

saturated with air at 15°C [16]. However, the pipes were not always at 15OC: when the heating

system was operating they were closer to 70 "C. Figure 6 shows that the corrosion rate should go

up by ~2.7 times over this temperature interval. The heating system was generally used only for 6

months out of each year; on average the corrosion rate was probably x 1.8 times greater than it

would have been at 20 "C. This would give a corrosion rate of x0.09-0.27 mm/year. If it is assumed

that rain-water had been leaking into the building for x 7 years, the depth of attack would be x 0.6-

1.9 mm. If the steel develops pitting corrosion, the rate of attack in the pit can be up to 10 times the

rate of general corrosion [ 161. In this case, the pits would easily be capable of perforating the wall