Page 356 - Finite Element Modeling and Simulations with ANSYS Workbench

P. 356

Introduction to Fluid Analysis 341

(a) (b)

Pressure Shear strain rate

Contour 1 Contour 1

3.820e-005 7.329e-002

3.105e-005 6.600e-002

2.390e-005 5.871e-002

1.674e-005 5.142e-002

9.590e-006 4.412e-002

2.438e-006 3.683e-002

–4.715e-006 2.954e-002

–1.187e-005 2.225e-002

–1.902e-005 1.495e-002

–2.617e-005 7.661e-003

–3.333e-005 3.685e-004

[Pa] [sˆ–1]

(c) (d)

Turbulence kinetic energy Velocity

Contour 2 Streamline 1

6.714e-006 7.669e-003

6.052e-006

5.390e-006

4.728e-006 5.763e-003

4.066e-006

3.404e-006 3.858e-003

2.742e-006

2.080e-006

1.418e-006 1.952e-003

7.558e-007

9.375e-008 4.635e-005

[mˆ2 sˆ–2] [m sˆ–1]

(e)

Velocity

Vector 1

7.669e-003

5.752e-003

3.835e-003

1.917e-003

0.000e-000

[m sˆ–1]

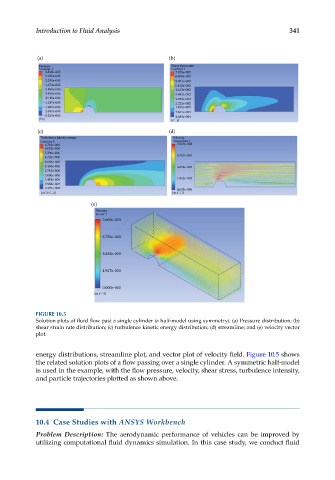

FIGURE 10.5

Solution plots of fluid flow past a single cylinder (a half-model using symmetry). (a) Pressure distribution; (b)

shear strain rate distribution; (c) turbulence kinetic energy distribution; (d) streamline; and (e) velocity vector

plot.

energy distributions, streamline plot, and vector plot of velocity field. Figure 10.5 shows

the related solution plots of a flow passing over a single cylinder. A symmetric half-model

is used in the example, with the flow pressure, velocity, shear stress, turbulence intensity,

and particle trajectories plotted as shown above.

10.4 Case Studies with ANSYS Workbench

Problem Description: The aerodynamic performance of vehicles can be improved by

utilizing computational fluid dynamics simulation. In this case study, we conduct fluid