Page 240 - Fluid Mechanics and Thermodynamics of Turbomachinery

P. 240

Centrifugal Pumps, Fans and Compressors 221

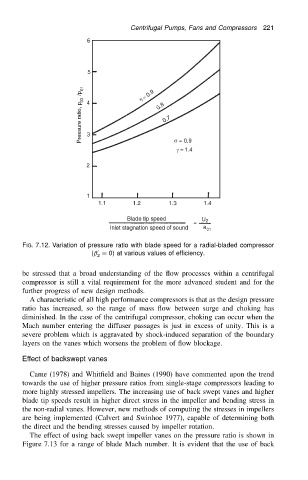

FIG. 7.12. Variation of pressure ratio with blade speed for a radial-bladed compressor

0

(ˇ D 0) at various values of efficiency.

2

be stressed that a broad understanding of the flow processes within a centrifugal

compressor is still a vital requirement for the more advanced student and for the

further progress of new design methods.

A characteristic of all high performance compressors is that as the design pressure

ratio has increased, so the range of mass flow between surge and choking has

diminished. In the case of the centrifugal compressor, choking can occur when the

Mach number entering the diffuser passages is just in excess of unity. This is a

severe problem which is aggravated by shock-induced separation of the boundary

layers on the vanes which worsens the problem of flow blockage.

Effect of backswept vanes

Came (1978) and Whitfield and Baines (1990) have commented upon the trend

towards the use of higher pressure ratios from single-stage compressors leading to

more highly stressed impellers. The increasing use of back swept vanes and higher

blade tip speeds result in higher direct stress in the impeller and bending stress in

the non-radial vanes. However, new methods of computing the stresses in impellers

are being implemented (Calvert and Swinhoe 1977), capable of determining both

the direct and the bending stresses caused by impeller rotation.

The effect of using back swept impeller vanes on the pressure ratio is shown in

Figure 7.13 for a range of blade Mach number. It is evident that the use of back