Page 179 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 179

Compressor Best Practices Best Practice 3 .13

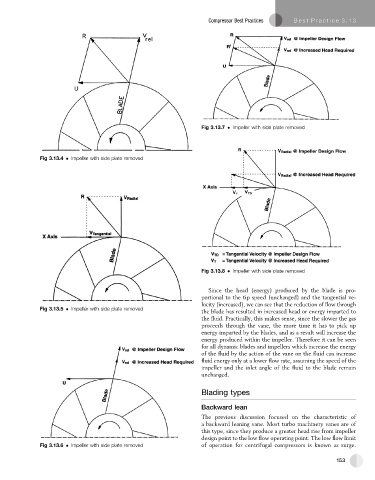

Fig 3.13.7 Impeller with side plate removed

Fig 3.13.4 Impeller with side plate removed

Fig 3.13.8 Impeller with side plate removed

Since the head (energy) produced by the blade is pro-

portional to the tip speed (unchanged) and the tangential ve-

locity (increased), we can see that the reduction of flow through

Fig 3.13.5 Impeller with side plate removed

the blade has resulted in increased head or energy imparted to

the fluid. Practically, this makes sense, since the slower the gas

proceeds through the vane, the more time it has to pick up

energy imparted by the blades, and as a result will increase the

energy produced within the impeller. Therefore it can be seen

for all dynamic blades and impellers which increase the energy

of the fluid by the action of the vane on the fluid can increase

fluid energy only at a lower flow rate, assuming the speed of the

impeller and the inlet angle of the fluid to the blade remain

unchanged.

Blading types

Backward lean

The previous discussion focused on the characteristic of

a backward leaning vane. Most turbo machinery vanes are of

this type, since they produce a greater head rise from impeller

design point to the low flow operating point. The low flow limit

Fig 3.13.6 Impeller with side plate removed of operation for centrifugal compressors is known as surge.

153